Electrification and Renewable Energy Integration

Electric Heating Technologies in Modern Cracking Furnaces

Electric heating tech like induction and resistance heating is starting to replace those old fossil fuel burners in cracking furnaces across many industrial settings. The benefits? Better efficiency and way fewer emissions than what we've been getting from traditional systems. Let's break it down a bit. Induction heating works by generating an electromagnetic field that heats up the inside of the furnace, whereas resistance heating simply runs electric current through materials to create heat. When compared side by side with older methods, these newer electric options actually cut down on energy usage quite substantially. Some plants report reductions of around 30% in their overall power requirements after making the switch, which makes a big difference when looking at long term operating costs.

Electric heating systems are getting smarter by the day thanks to new tech integrations. With these upgrades, operators can now keep tabs on system performance minute by minute and tweak settings as needed, which cuts down on wasted energy and saves money in the long run. Switching away from old school fossil fuel systems to electric alternatives has been shown to slash carbon output by around 30% in cracking furnaces, making this shift pretty much mandatory for any refinery wanting to cut their carbon footprint. Take a look at what's happening at major oil processing plants across the country. Many report not just better bottom lines but also cleaner air around their facilities after implementing these electric solutions.

Role of Renewable Energy in Oil Refinery Decarbonization

Renewables like solar and wind are becoming increasingly important for oil refineries trying to cut down on carbon emissions. When refineries start using these cleaner energy options instead of traditional fossil fuels, they naturally emit fewer greenhouse gases overall. Take solar thermal systems as an example many plants have started installing them to handle the heat needed for various refining processes. This switch not only helps meet environmental regulations but also makes good business sense in the long run as companies face growing pressure from investors and regulators alike to green up their operations.

Renewable energy has real scalability potential, which is why it plays such a key role in reaching those long term sustainability targets many industries are chasing. Looking at actual numbers from pilot programs, refineries have managed to hit their green goals without sacrificing day to day operations. The oil and gas sector in particular has seen some major shifts lately. Companies like Shell and BP are making public commitments to switch over to cleaner tech solutions. Going green isn't just good for the planet either. When businesses invest in renewables now, they're actually building protection against all those unpredictable swings we see in fossil fuel prices. Makes sense when you think about it this way.

Sustainable Feedstock and Circular Economy Solutions

Bio-Based Feedstocks for Crude Oil Refinery Alternatives

Bio based feedstocks are starting to replace traditional crude oil in refineries, providing a greener way to make energy. Take for instance biofuels made from algae and farm waste these materials signal a real move away from our reliance on fossil fuels. Switching to these bio sources cuts down carbon emissions while turning trash into fuel, which supports what some call a circular economy. Studies show that these options might actually cover a good chunk of what refineries need for their processes, reducing how much they depend on oil and gas.

Bio-based feedstocks offer advantages that go well beyond just being good for the environment. When companies start incorporating these renewable materials into their operations, they actually cut down on carbon output quite substantially while helping push forward those international efforts to reduce greenhouse gases. Industry insiders keep pointing out how crucial it is to ramp up production of bio-based options so refineries can switch over from traditional sources. There are definitely hurdles still standing in the way when it comes to producing enough material at scale and keeping costs reasonable. But looking at what's happening right now with research and development, there seems real potential for bio-based alternatives to become a major player in the petrochemical sector going forward.

Plastic Waste Recycling via Advanced Cracking Equipment

New developments in cracking equipment have become game changers for plastic waste recycling, helping recover resources while cutting down on environmental damage. These machines work by breaking down plastic waste into raw materials that industries can reuse in their manufacturing processes. With landfills overflowing and oceans choked with plastic debris, there's real potential here. Many factories still struggle with what to do with all this waste, so implementing these cracking technologies could turn a big problem into something useful and profitable at the same time.

The numbers tell us that globally, we're only recycling around 9% of all plastic waste right now. But there's hope on the horizon thanks to new cracking tech that actually breaks down plastics at molecular level. When industries start using these methods, they recover way more material than before, basically transforming trash piles into something useful again. Tech startups have been teaming up with local waste collectors across Europe already, creating real world applications where communities see money coming back into their pockets while keeping landfills from overflowing. Looking ahead, researchers believe these techniques will get even better over time. We might see processing plants operating twice as fast without compromising quality soon enough. The bottom line remains clear though: cleaner oceans and healthier economies go hand in hand when we treat plastic waste as raw material rather than garbage.

Innovative Cracking Equipment for Resource Recovery

Tyre Cracking Furnace for Fuel Oil and Carbon Black Production

Tyre cracking furnaces are really changing how we deal with old tires, turning them into useful stuff like fuel oil and carbon black. Basically what happens is these furnaces heat up tires until they break apart, creating products that find their way into different sectors. The fuel oil comes out of this process and works as an alternative energy option. Carbon black gets used all over the place too, especially in making new tires and printing inks. Beyond just getting energy back from waste materials, these furnaces cut down on landfill space needed for tire disposal, which helps keep our environment cleaner. Industry reports suggest around 40 percent of fuel oil and about 35 percent carbon black can be recovered through this method. For businesses looking to invest in greener tech options, this seems like something worth considering given current market trends toward sustainable practices.

Continuous Waste Tire Pyrolysis Plant Machinery

The continuous pyrolysis tech represents a major step ahead when it comes to recycling old tires effectively. While traditional batch systems need frequent stops and starts, continuous pyrolysis facilities run nonstop throughout production cycles. This constant operation means higher output rates and fewer delays during maintenance periods. The process relies on specialized cracking machinery that breaks down tires into valuable materials like tire-derived oil and usable carbon black residue. According to industry reports, these continuous operations can actually produce twice as much material per unit time compared to older approaches. Environmental concerns have driven significant improvements too, with modern installations incorporating emission control systems and energy recovery mechanisms. Many waste management experts now see pyrolysis as the go-to solution for handling discarded tires, mainly because it ticks all boxes for both environmental responsibility and cost effectiveness in long term operations.

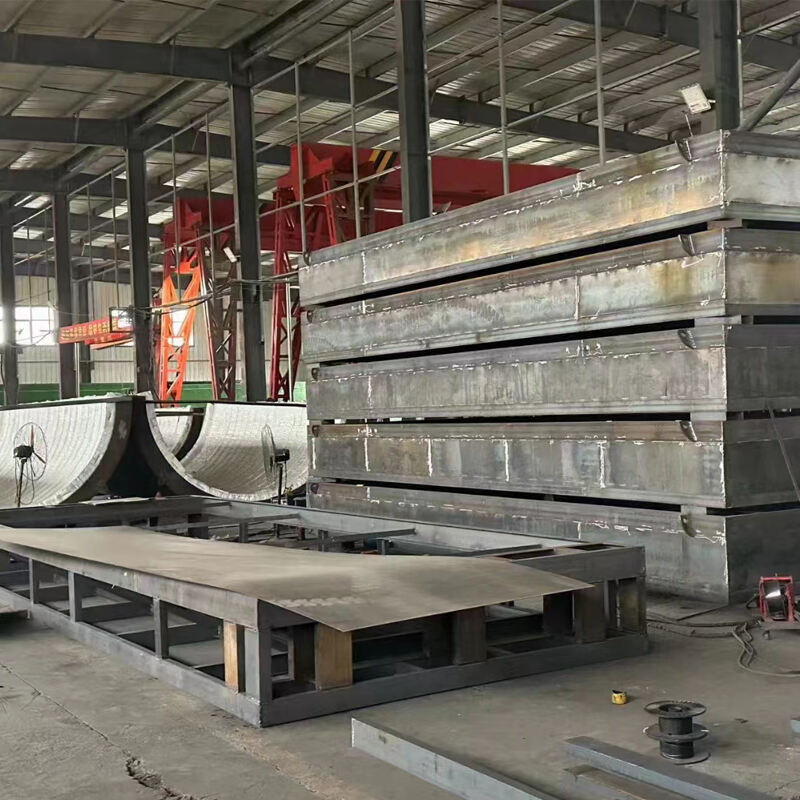

Rubber Cracking Furnace with Core Engine Motor Integration

Adding core engine motor tech to rubber cracking furnaces actually makes them run better and produce more stuff. When companies throw in some automation and those internet-connected devices too, everything gets even better. Real time monitoring lets operators tweak things on the fly which means products come out looking pretty much the same every time. Look at what happened at several big refineries recently - after installing these systems, their numbers went up across the board while pollution levels dropped off significantly. The industry analysts are seeing this trend continuing strong into the future. More and more businesses want greener ways to recover resources without breaking the bank, so there's going to be plenty of room for growth here. For manufacturers trying to cut costs and reduce waste at the same time, these improvements aren't just nice to have anymore.

Collaborative Innovations and Industry Partnerships

Global Initiatives like the Cracker of the Future Consortium

The Cracker of the Future Consortium is shaking things up in the petrochemical world with its ambitious plan to transform traditional cracking methods through international cooperation. What sets this group apart is their focus on replacing fossil fuel dependency in steam crackers with renewable electricity sources. Big names in the industry have joined forces to fund joint R&D projects that could cut down carbon footprints substantially while still meeting production demands. While nobody can predict exact results yet, early indicators suggest lower operating expenses alongside greener operations. And let's face it, if major players start adopting these new techniques across their facilities, we might actually see real progress toward cleaner industrial processes instead of just talking about it.

The consortium has kicked off multiple pilot programs and projects that demonstrate real world partnerships and tech transfers happening right now. Take for instance how BASF worked alongside SABIC and Linde to get their electric steam cracking demo plant up and running. Industry insiders keep talking about teamwork being critical these days. They argue that when companies join forces on initiatives like this, it actually helps shape where refining tech is headed while making progress toward that circular carbon economy everyone keeps mentioning lately.

Public-Private Partnerships Driving Fractional Distillation Advances

Public private partnerships are really making a difference when it comes to pushing forward fractional distillation tech. They bring in big bucks for research while also encouraging companies to share what works best across the industry. These joint efforts help create new methods that make oil refineries run better while cutting down on those nasty emissions we all want to avoid. Take a look at what's happening lately - many of these partnerships are working hard to plug in solar power and wind energy into traditional setups. At the same time, they're figuring out smarter ways to manage day to day operations. The result? Cleaner air around refinery sites and generally better environmental stats across the board for participating facilities.

Some joint ventures between governments and businesses have made real progress lately, with certain programs becoming sort of industry standards. Take Germany for example where state support has gone into making steam cracking processes run on electricity rather than fossil fuels, which cuts down emissions quite a bit. Industry insiders keep pointing out how important working together actually is when it comes to tackling problems in oil refining. These kinds of partnerships tend to bring fresh ideas to the table while also sharing costs, something that makes sense if companies want to move forward without breaking the bank on sustainability measures.

Through these collaborative efforts, both global initiatives and public-private partnerships foster a culture of innovation and sustainability in the oil refining industry, ensuring that the sector evolves in alignment with environmental goals.

Hot News

Hot News