The Importance of Cracking Furnaces in the Refining Process

Cracking furnaces play a key role in oil refineries, basically turning those heavy hydrocarbon compounds into lighter stuff that people actually want - think gasoline, diesel fuel, and other refined products. The actual process works by breaking apart those big molecules from distilled crude oil into smaller ones. Refiners consider this breakdown step pretty important for getting better yields and maintaining product quality across the board. Data from the US Energy Information Administration shows why these operations matter so much for our energy landscape. Without them, we wouldn't be able to meet demand for all sorts of petroleum-based goods while keeping distribution systems running efficiently throughout the country.

Cracking plays a major role in the overall refining process. The way we crack crude oil affects both how much product comes out and its quality, which makes it really important for fractional distillation operations at refineries. When refiners get better results from their cracking processes, they produce more valuable stuff like high grade diesel fuel and top tier gasoline that sells well in the market. The whole point of cracking is basically turning those heavy hydrocarbons into lighter fractions that people actually want to buy. This transformation boosts what refineries can sell across different markets, meeting needs from everyday consumers all the way up to big industrial users who need consistent supply chains.

Cracking processes aren't just helpful they're actually essential if refineries want to run efficiently and make money. When refiners can consistently turn those stubborn heavy crude fractions into valuable lighter products like gasoline and diesel, their bottom line gets a real boost. The impact goes way beyond just production numbers too. Logistics systems need to adapt, inventory management becomes trickier, and the whole supply chain has to adjust accordingly across the oil sector. With consumers demanding cleaner burning fuels at record levels worldwide, modern cracking furnaces have become must-have equipment for any refinery serious about staying ahead of the competition and keeping pace with what markets want these days.

The Role of Cracking in Modern Oil Refineries

In oil refineries across the globe, cracking remains one of the most important processes for improving fuel quality. When complex hydrocarbons get broken down into simpler components during this operation, we end up with much better performing fuels. Beyond just cleaning out unwanted impurities, modern cracking techniques actually help ensure compliance with those ever tightening engine specifications set by regulators worldwide. Take crude oil molecules that are way too big to work properly in vehicles or machinery. Refineries crack them apart to make premium grade gasoline, diesel blends, and specialty fuels needed throughout transportation networks and manufacturing sectors. And let's face it folks, when refiners manage their cracking operations well, entire supply chains benefit from reduced waste and lower production costs associated with these vital energy products.

Modern oil refineries rely on various cracking techniques, each offering different benefits depending on what needs to be processed. Thermal and catalytic cracking stand out as the main approaches. Thermal cracking works by applying intense heat and pressure to split those tough heavy hydrocarbons apart. Catalytic cracking takes a different route, using special substances called catalysts to speed things up without needing such extreme conditions. Thermal tends to handle the really thick stuff, whereas catalytic is often preferred when the goal is creating high octane fuel quickly. Picking between these methods matters a lot for how well a refinery runs and what kind of products come out the other end. These techniques show just how far technology has come in this field, allowing plants to fine tune operations based on market demands and raw material characteristics.

Key Technologies in Cracking Furnaces

Steam cracking stands as one of the key technologies inside those big industrial furnaces, where heat and pressure work together to split apart complex hydrocarbons into simpler molecules called olefins. Most commonly seen across petrochemical plants worldwide, this technique transforms raw materials like naphtha or ethane into valuable building blocks such as ethylene and propylene that go on to make countless everyday products we rely on daily. Inside these massive systems, operators blast the feedstock with intense heat typically around 800°C give or take while introducing steam into the mix. Recent advancements have made all the difference though. Newer coil designs along with three dimensional furnace configurations help cut down on unwanted carbon buildup (commonly known as coke) while making better use of energy resources. Some facilities report seeing their operational costs drop by roughly twenty percent after implementing these modern upgrades.

Catalytic cracking stands out as one of those essential processes in petroleum refining, mainly because it boosts both yield and quality of products. What makes it different from steam cracking? Well, catalytic cracking relies on special substances called catalysts to break down those big hydrocarbon molecules into smaller, more valuable components such as gasoline, diesel fuel, and various industrial chemicals. These catalysts speed things up chemically, so refineries can operate at much lower temperatures and pressures than traditional thermal methods require. The result? Higher efficiency rates and better control during the fractional distillation stage of crude oil processing. When we look at the bigger picture, catalytic cracking and similar technologies form the backbone of modern refining operations. They help produce all sorts of fuels and specialty chemicals that keep up with what markets need today while still making economic sense for operators.

Environmental Considerations of Cracking Furnaces

Cutting down on emissions from the cracking process matters a lot when it comes to meeting regulations and keeping our air clean. When crude oil gets cracked, all sorts of greenhouse gases and harmful stuff get released into the atmosphere, which really messes with the environment over time. Government agencies have been pushing hard for years now, setting tough rules so refineries don't pump out too much pollution. Many plants are investing in better tech these days too – things like those special low-NOx burners or switching to cleaner fuel sources actually work pretty well at bringing emissions down. The whole industry has woken up to this lately. Companies aren't just following the rules anymore; they're starting to see how their operations affect local communities and ecosystems in ways that go beyond simple compliance requirements.

Green approaches in oil refining, including things like energy recovery systems and better waste management, have started making their way into standard cracking furnace operations across many facilities. These energy recovery setups work by grabbing excess heat from the refining process and putting it back into the system, which saves money on fuel costs over time. On the waste front, refineries are now reusing water from cooling systems instead of dumping it away, and they've redesigned equipment to create fewer unwanted byproducts. For the oil industry, adopting these greener methods isn't just about looking good environmentally it actually helps them cut down on expenses too. As companies implement these changes throughout their operations, the overall ecological damage caused by fractional distillation processes in modern oil refineries continues to decrease year after year.

Products Related to Cracking Furnaces

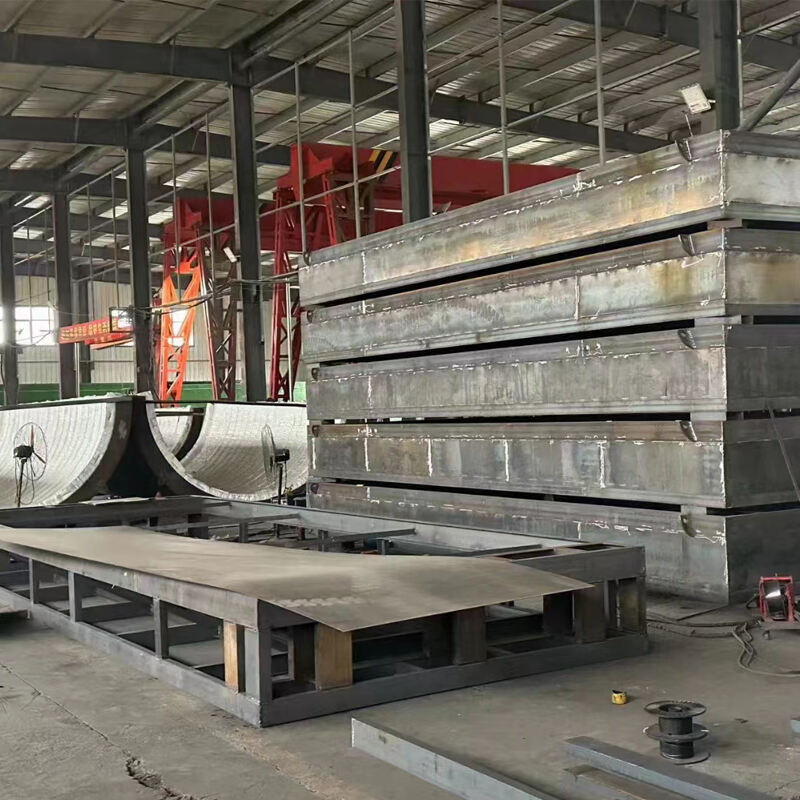

Cracking furnaces play a really important part in turning trash into something useful, making them key players in modern waste management systems. Take the Tyre Cracking Furnace for example it's built specifically to handle old tires and turn them into stuff people actually want like fuel oil and carbon black. These machines do double duty by helping deal with mountains of solid waste while at the same time creating products that fetch good prices on the market. For industries looking to go green without breaking the bank, this kind of technology offers a win-win solution that makes both environmental and economic sense.

The new continuous waste tire, plastic and rubber pyrolysis plant machinery is making waves in the industry thanks to its continuous processing capability. What makes this equipment stand out is that it handles both tire scraps and plastic waste at impressive efficiency levels while creating valuable outputs such as pyro gas and refined oil for sale. The system relies on advanced thermal cracking methods which help extract maximum resources from waste materials. This approach significantly reduces what ends up in landfills and cuts down harmful emissions compared to traditional disposal methods. Many manufacturers are now turning to these systems as they seek ways to turn their waste streams into profit centers while meeting increasingly strict environmental regulations.

Lastly, the New Tire/Rubber Cracking Furnace, specialized for pyrolysis oil equipment, revolutionizes resource recovery from scrap rubber. By effectively breaking down rubber waste into components such as oil and carbon black, this equipment supports the recycling industry's drive towards sustainability and economic efficiency.

Future Trends in Cracking Technology

New developments in refining techniques are changing the game when it comes to cracking technology across the board. Digital tools and automated systems have become game changers for managing crude oil refineries these days. Take for instance the way many plants now use sophisticated 3D models along with smart process optimization software. These technologies aren't just theoretical anymore they actually work on the shop floor. Look at what happened with the IMPROOF initiative where one refinery cut down its CO2 output by no less than 30%. That kind of improvement shows companies that investing in better tech isn't just good for the bottom line it makes sense environmentally too, something that matters increasingly in today's regulatory climate.

The road ahead for cracking tech in oil and gas appears to head in a greener direction. More companies are starting to experiment with different raw materials and clean energy options, which gradually changes how things work across the sector. Some operations already test biofuels mixed into traditional refining methods, while others explore ways to power distillation units using renewable electricity sources. This shift isn't happening overnight but represents real progress in reducing greenhouse gas emissions from fossil fuel processing. What we see unfolding suggests these technologies won't disappear anytime soon despite environmental concerns. Instead they seem likely to adapt over time as regulations tighten and market demands push for cleaner alternatives without sacrificing profitability.

Hot News

Hot News