Understanding Industrial Pyrolysis Technology for Modern Waste Management

As environmental concerns grow and landfill space diminishes, pyrolysis equipment has emerged as a revolutionary solution for waste management and recycling initiatives. This advanced technology transforms various waste materials into valuable resources through a thermochemical decomposition process, offering both environmental and economic benefits. Whether you're a waste management professional, facility operator, or environmental consultant, selecting the right pyrolysis equipment is crucial for project success.

The global waste-to-energy market continues to expand, with pyrolysis technology playing an increasingly vital role. This sophisticated process not only helps reduce waste volume but also generates useful byproducts such as bio-oil, syngas, and char, making it an attractive option for sustainable waste management solutions.

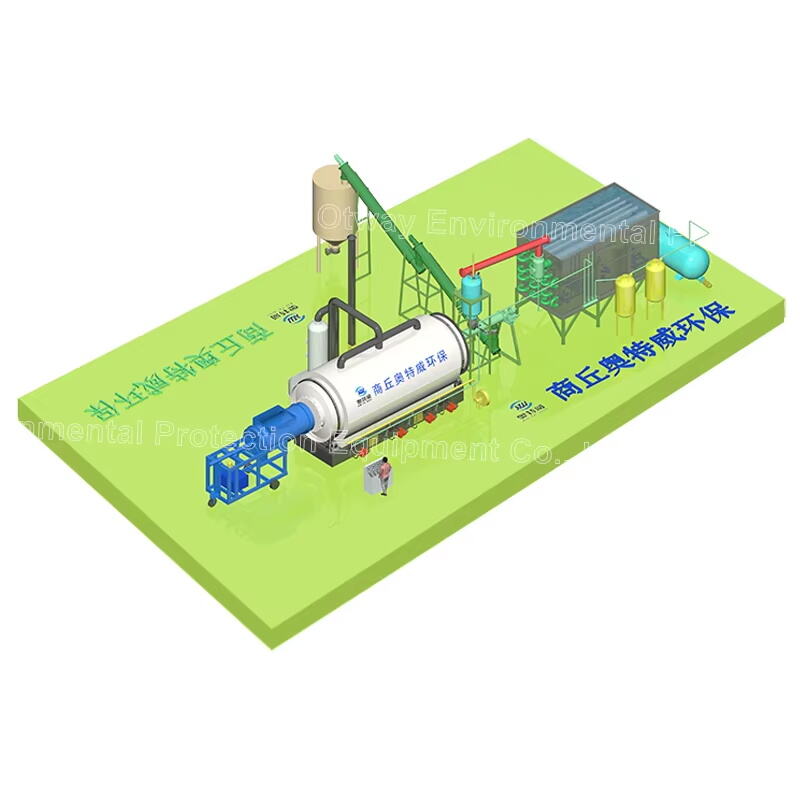

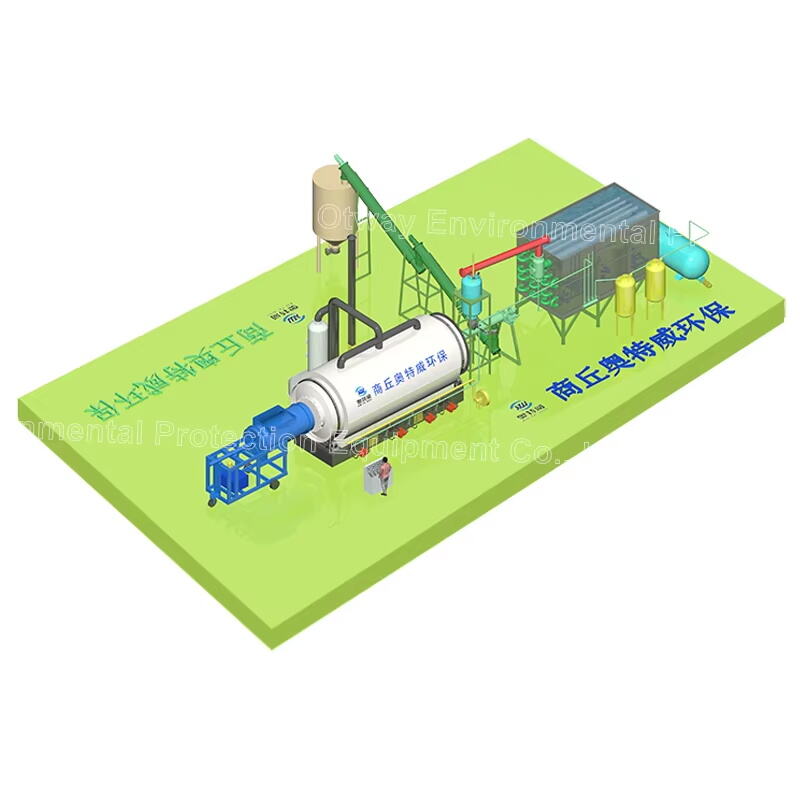

Key Components of Industrial Pyrolysis Systems

Reactor Design and Configuration

The heart of any pyrolysis equipment is its reactor system. Modern reactors come in various configurations, including fixed bed, fluidized bed, and rotary kiln designs. Each type offers specific advantages depending on the waste feedstock and desired outputs. Fixed bed reactors, for instance, excel in processing uniform materials, while fluidized bed systems handle varying waste streams more effectively.

Temperature control mechanisms and heating systems are crucial aspects of reactor design. Advanced pyrolysis equipment incorporates precise temperature monitoring and adjustment capabilities, ensuring optimal thermal decomposition conditions for different waste materials.

Material Handling and Feeding Systems

Efficient material handling systems are essential for continuous operation. Modern pyrolysis equipment features automated feeding mechanisms, including conveyors, screws, or pneumatic systems, designed to maintain consistent feed rates and prevent system blockages. These systems must be robust enough to handle various waste materials while maintaining operational safety.

Pre-treatment equipment, such as shredders and dryers, plays a vital role in preparing waste materials for processing. The right combination of these components ensures optimal feedstock condition before entering the pyrolysis chamber.

Technical Specifications and Performance Parameters

Processing Capacity and Throughput

When evaluating pyrolysis equipment, processing capacity is a primary consideration. Systems range from small-scale units processing a few tons per day to industrial-scale installations handling hundreds of tons daily. The key is matching equipment capacity with project requirements while allowing for future expansion.

Throughput efficiency depends on various factors, including feedstock characteristics, moisture content, and particle size. Advanced pyrolysis systems offer flexibility in processing rates while maintaining consistent product quality.

Energy Efficiency and Recovery Systems

Modern pyrolysis equipment incorporates sophisticated heat recovery and energy management systems. These features minimize operational costs while maximizing resource recovery. Heat exchangers and thermal oil systems help maintain optimal processing temperatures while reducing energy consumption.

The integration of energy recovery systems allows facilities to utilize produced syngas for power generation or process heating, improving overall system efficiency and reducing operating costs.

Environmental and Safety Considerations

Emission Control Systems

Environmental compliance is critical in pyrolysis operations. State-of-the-art pyrolysis equipment includes comprehensive emission control systems, featuring gas cleaning units, particulate filters, and scrubbers. These systems ensure operations meet or exceed local environmental regulations while minimizing environmental impact.

Regular monitoring and maintenance of emission control systems are essential for sustained environmental compliance and optimal performance. Advanced monitoring equipment provides real-time data on emissions and system performance.

Safety Features and Controls

Safety is paramount in pyrolysis operations. Modern equipment incorporates multiple safety features, including emergency shutdown systems, pressure relief valves, and temperature control mechanisms. Automated control systems monitor critical parameters and respond to potential issues before they become problems.

Operator safety features, such as proper insulation, guard rails, and emergency access points, should be standard on all pyrolysis equipment. These elements protect personnel while ensuring smooth operation.

Maintenance and Operational Requirements

Preventive Maintenance Schedules

Regular maintenance is crucial for optimal performance of pyrolysis equipment. Manufacturers provide detailed maintenance schedules covering daily, weekly, and monthly tasks. Following these schedules helps prevent unexpected downtime and extends equipment life.

Key maintenance activities include inspection of wear parts, cleaning of critical components, and regular calibration of control systems. Documentation and tracking of maintenance activities help optimize equipment performance and reliability.

Operator Training and Support

Successful operation of pyrolysis equipment requires well-trained personnel. Comprehensive training programs should cover equipment operation, safety procedures, and troubleshooting. Regular updates and refresher courses ensure operators maintain proficiency with the technology.

Technical support from equipment manufacturers should include remote assistance, on-site service, and access to spare parts. This support network is crucial for minimizing downtime and maintaining optimal operation.

Economic Considerations and ROI Analysis

Capital Investment Requirements

Initial investment in pyrolysis equipment varies significantly based on capacity and features. Beyond equipment costs, considerations include installation, site preparation, and auxiliary systems. A thorough analysis of capital requirements helps ensure project viability.

Financing options and payment terms from equipment suppliers can significantly impact project feasibility. Many manufacturers offer flexible payment plans or leasing options to help manage initial capital requirements.

Operating Costs and Revenue Streams

Understanding operating costs is crucial for project success. Key factors include energy consumption, labor requirements, maintenance expenses, and consumable materials. Advanced pyrolysis equipment often offers lower operating costs through improved efficiency and automation.

Revenue potential from recovered materials and energy production should be carefully evaluated. Market analysis for pyrolysis products, including bio-oil, char, and syngas, helps determine potential returns on investment.

Frequently Asked Questions

What types of waste materials can pyrolysis equipment process?

Pyrolysis equipment can process various waste materials, including plastic waste, biomass, tires, and certain industrial wastes. The specific capability depends on the equipment design and configuration. Most modern systems can handle multiple waste streams with proper pre-treatment.

How long does it take to install and commission new pyrolysis equipment?

Installation and commissioning typically take 3-6 months, depending on system size and complexity. This timeline includes site preparation, equipment installation, testing, and operator training. Proper planning and coordination with the manufacturer can help optimize the implementation schedule.

What are the typical maintenance requirements for pyrolysis equipment?

Maintenance requirements vary by system but generally include daily inspections, weekly cleaning, and monthly comprehensive checks. Key components requiring regular attention include feed systems, reactor components, and emission control equipment. Manufacturers provide detailed maintenance schedules and recommendations.

How does weather affect pyrolysis equipment operation?

Modern pyrolysis equipment is designed to operate in various weather conditions. However, extreme temperatures may affect system efficiency. Indoor installation and proper insulation help minimize weather impacts. Advanced control systems adjust operations to maintain optimal performance regardless of external conditions.

Hot News

Hot News