Core Principles of Continuous Cracking Systems

Thermal Decomposition Process

Thermal decomposition plays a central role in continuous cracking systems, breaking down complex molecules at very high temps that turn raw materials into useful products. During cracking operations, hydrocarbons get heated past around 450 degrees Celsius, causing them to split apart at the molecular level. The result? Lighter substances such as gasoline emerge, something industries rely on across many sectors including transportation fuels and chemical manufacturing. Industry research shows these breakdown processes can be remarkably efficient sometimes hitting nearly 95% effectiveness when everything works right. These impressive efficiency numbers point toward some serious potential for cleaner energy production methods and better resource utilization across different manufacturing contexts.

Automated Material Handling

Material handling systems that are automated boost how well continuous cracking systems work day to day. Most setups include things like conveyor belts and automatic feed mechanisms that take care of moving materials between different processing stages without needing workers to handle everything manually. When connected to IoT tech, these systems let operators watch material movement in real time, which means they can tweak settings on the fly for better results. Real world implementations show pretty impressive gains from going automated. Some plants report up to 30% higher throughput rates while cutting down on staff needed for material handling tasks. The benefits go beyond just saving money too. Automated systems create more consistent operations across shifts, cut down on mistakes made by tired workers, and reduce the need for someone to constantly monitor every step of the process. For companies running cracking operations, investing in smart material handling solutions pays off through improved reliability, lower operating costs, and better overall performance metrics.

Technological Advancements in Modern Cracking Systems

Micro-Negative Pressure Pyrolysis

The new micro-negative pressure approach to pyrolysis represents a major leap forward compared to older methods because it actually creates better conditions for thermal efficiency and produces much cleaner byproducts. When materials break down under these low pressure conditions, the whole process happens faster since there's less resistance from the atmosphere. This means less energy gets used up and the end products tend to be higher quality overall. Real world tests have shown some impressive results too. Factories that switched to this technique report getting about 30% more usable material from their feedstock while cutting down on those nasty smoke emissions by nearly half. That kind of performance naturally fits right into current green initiatives across many sectors. More manufacturers are starting to look seriously at making the switch not just for environmental reasons but also because it simply works better economically in the long run.

Real-Time Process Monitoring

Bringing real time monitoring tech into cracking systems through sensors and data analysis has completely changed how operations run and boosted safety across the board. Modern setups use all sorts of sensors constantly collecting information, which gets processed right away to adjust what's happening during production. This instant feedback means plants can keep running smoothly most of the time, cutting down on those surprise shutdowns that cost so much money. Industry stats show pretty clearly that companies implementing these monitoring systems see fewer unexpected outages each year, sometimes saving millions in lost productivity. The bottom line? Better monitoring doesn't just save cash it actually makes whole operations more dependable, something every plant manager wants when dealing with complex chemical processes day after day.

Operational Benefits of Continuous Production

24/7 Processing Capabilities

Continuous production really boosts throughput since it allows factories to run all day every day without stopping. Industries that want to crank out more products while keeping up with growing demand find this kind of constant operation absolutely essential. Traditional batch systems just don't cut it anymore because they need regular breaks for maintenance and setup changes. Continuous systems keep going straight through, which means factories can produce way more goods overall. Take chemical manufacturing for example most plants running continuously see major gains in how efficiently they work and spend less time idling between batches. The bottom line gets better too when operations stay consistent across shifts. Labor costs drop off significantly because there's no need for extra workers during changeovers, and machines last longer since they aren't constantly being started and stopped. Chemical and pharmaceutical companies have been doing this for years now, and their bottom lines tell the story why so many other industries are starting to adopt similar 24 hour approaches despite the initial investment required.

Waste-to-Energy Conversion Efficiency

Getting better at turning waste into energy matters a lot for sustainability because it cuts down on trash while making something useful out of it. Cracking systems today work much better than they used to, getting more power from the same amount of garbage. When waste gets converted into actual energy, we don't need to dump so much stuff in landfills anymore, plus we get cleaner power options. Look at some real world examples where businesses slashed what goes into landfills just by adopting these waste to energy methods. Numbers show that these processes cut down pollution quite a bit too, which means good things for both our environment and our energy needs. As more people care about going green, waste to energy tech becomes really important for hitting those environmental targets and helping create an economy where nothing goes to waste.

Multi-Purpose Cracking Reactors

Cracking reactors designed for multiple purposes bring real value to industrial settings because they can handle all sorts of different feedstocks within one system. The ability to switch between materials means plants stay flexible when production needs change throughout the day or week something that matters a lot in sectors where process adjustments happen regularly. These units cut down on downtime since operators don't have to swap out equipment every time they want to process something new. Plus, companies save money on capital expenditures because there's no need to buy separate machines for each type of material. Looking at what's happening across manufacturing right now, we see a clear movement toward equipment that adapts rather than specializes. Many chemical processing facilities report improved results after switching to this kind of reactor setup, finding it works well whether they're dealing with light hydrocarbons or heavier crude oil fractions.

Cracking operations have started leaning heavily toward these reactors because they just work better for most applications. Plants report saving money on running costs while getting much more flexibility in how they operate day to day. Real world results back this up across different sectors from petrochemicals to food processing. What's really pushing this change? Companies want to get the most out of every dollar spent but still maintain product standards. Many manufacturers now see these reactors not just as equipment upgrades but essential tools for staying competitive in tight markets where waste means lost profits.

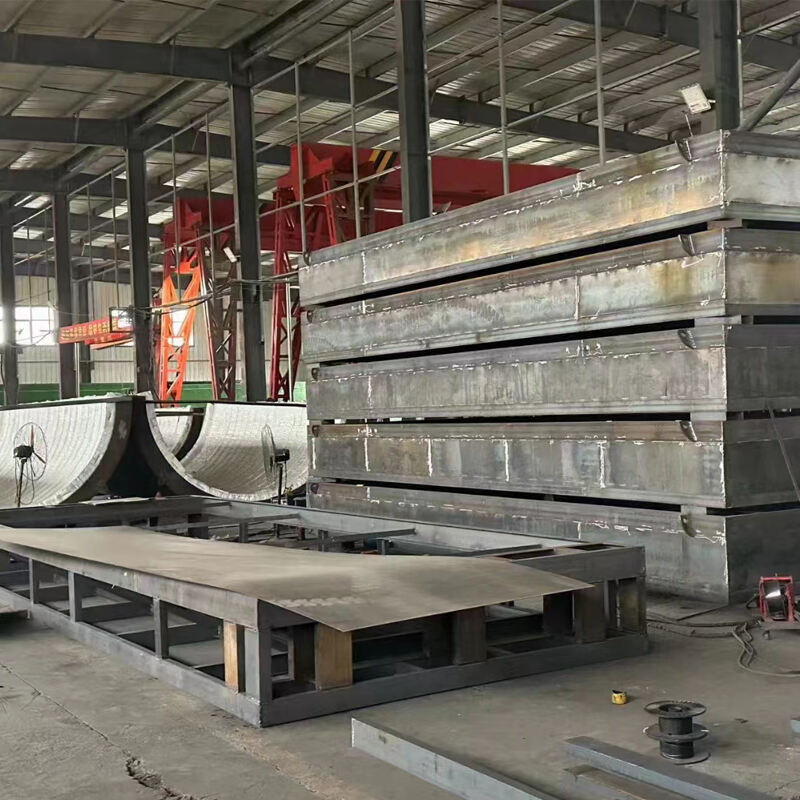

Continuous Feed Pyrolysis Plants

The continuous feed pyrolysis plants are changing how we think about traditional pyrolysis methods because they simply work better than those old batch systems. What makes them special? Well, these setups let material keep flowing in without stopping, so everything runs smoother and gets done faster. The big difference is that there's hardly any waiting around between batches. When a system can run non-stop day after day, it naturally produces more output than something that has to pause regularly. Look at what happened at several facilities recently where switching to continuous feed made their operations way more efficient. Some saw production jump by nearly 40% within months. That kind of real-world performance shows why more companies are looking seriously at making the switch from batch processing to continuous feed technology for their pyrolysis needs.

The latest tech improvements in pyrolysis really make those continuous operations work better over time, cutting costs and making things run smoother in the long run. Take automated controls for example they let operators manage how much material goes into the system and keep temperatures just right, which means the whole pyrolysis process runs at peak efficiency. Many manufacturers are looking for ways to be greener without breaking the bank, so when they see what continuous feed systems can do, it makes sense why companies across different sectors are starting to adopt them more widely these days.

Tire-to-Fuel Conversion Systems

Turning old tires into fuel is something that comes with its share of headaches but also offers some pretty good rewards. The biggest problem people face is figuring out how to break down those tough rubber compounds effectively while getting as much energy back as possible. Luckily, recent improvements in tire conversion technology have made things a lot easier than they used to be. Modern systems basically heat up shredded tires in oxygen-free conditions through a process called pyrolysis. This creates usable products like fuel oil, combustible gas, and solid carbon residue. What's great about this approach is that it turns what would otherwise end up in landfills into actual resources. Some studies indicate these methods not only cut down on landfill waste but also help reduce our reliance on traditional petroleum sources over time.

Successful implementations globally provide compelling evidence of the system's benefits. The reduced waste tire generation and increased fuel yield present a sustainable solution acknowledging both environmental and economic benefits. As more industries recognize the potential in tire-to-fuel conversion, the systems are increasingly integrated into comprehensive waste management strategies.

Modular Rubber Recycling Units

Modular units play a pivotal role in enhancing the efficiency of rubber recycling operations. These units are highly scalable and easily installed, making them suitable for various operational sizes and needs. By adopting a modular approach, industries can upscale their operations without significant downtime or infrastructure changes.

Real-world deployments of modular units demonstrate their positive impact on local environments by increasing recycling rates and reducing waste. Data from these deployments indicate that scalability paired with the ease of installation significantly boosts recycling efforts, offering a practical and flexible solution for rubber waste management.

Integrated Thermal Cracking Modules

Integrated thermal cracking modules offer a comprehensive solution by seamlessly incorporating into existing infrastructure. This integration enhances overall system performance, resulting in increased efficiency and reduced emissions. The holistic approach of these modules aligns with industry standards, focusing on sustainability and improved environmental footprint.

Numerous industry leaders advocate for integrated solutions due to their proven track record in boosting system efficacy and emission reduction. As companies strive for greener and more efficient operations, adopting integrated thermal cracking modules proves to be a decisive step forward, fostering long-term viability in environmental and operational performance.

Hot News

Hot News