Thermal Cracking Processes Explained

Thermal cracking stands out as a key method in managing waste by breaking down complicated organic stuff into basic hydrocarbons. When we apply this process, things like old plastics and rubber get turned into useful products such as oil, gas, and carbon black. This actually creates money streams while cutting back on our dependence on regular fossil fuels. Instead of just throwing away these materials, thermal cracking gives them new life as valuable commodities. The technology works particularly well for dealing with those stubborn non-biodegradable wastes that pile up in landfills across the country. Many waste treatment facilities are now adopting this approach because it makes good business sense and helps address environmental concerns at the same time.

Integration with Resource Recovery Systems

Adding cracking systems to waste recovery setups really boosts how much we can get back from trash, pulling out useful stuff that would otherwise go to waste. These systems take a broader view of waste management overall, which fits right into circular economy goals where garbage becomes raw material instead of just ending up in landfills. The EPA reports something pretty impressive here too: good recovery systems cut down on landfill waste by around 80 percent. That kind of reduction makes a huge difference for communities trying to be greener, especially when considering all the environmental costs associated with traditional disposal methods.

Technological Innovations in Cracking Systems

Automation and Continuous Processing

The waste management industry is undergoing major changes thanks to automated processing systems that keep running nonstop. These new technologies allow facilities to process mountains of garbage day after day without stopping for breaks. What makes this so valuable? Well, machines don't get tired or distracted, so there's fewer mistakes when sorting through trash. Plus, everything runs smoother from start to finish which saves money on labor costs. Companies that convert waste into energy are seeing better profits because of these improvements too. Some numbers floating around suggest productivity jumps anywhere between 25-30% once factories implement full automation. This isn't just theoretical stuff either many municipalities have already started adopting these systems to handle their growing waste problems more effectively.

Emission Control Technologies

With growing concerns about the environment, emission control tech has become essential for cracking systems these days. Modern filtration units and scrubbers work together to trap most pollutants before they get released into the air, which helps meet those tough environmental rules companies face. When plants install good emission control systems, studies show around half of the harmful stuff gets cut down. Environmental watchdogs back this up through their research findings. Beyond just meeting standards, these controls actually help businesses save money on fines while protecting local ecosystems from pollution damage. Many operators find it makes sense both environmentally and economically in the long run.

Leading Cracking Equipment for Sustainable Waste Processing

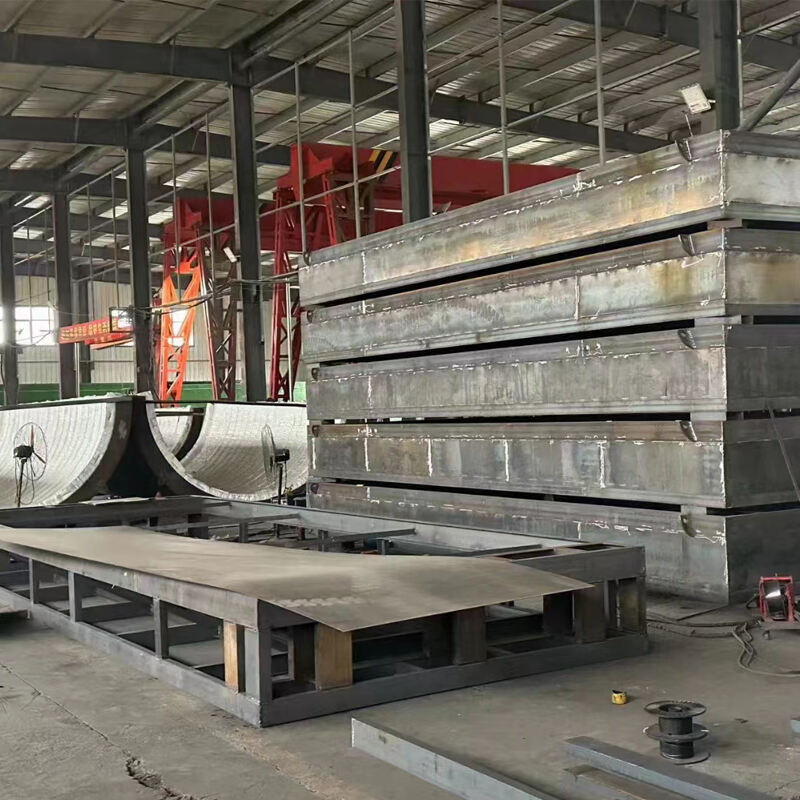

50Ton Fully Continuous Waste Oil Sludge Pyrolysis Plant

The 50 Ton Continuous Waste Oil Sludge Pyrolysis Plant represents a major step forward for handling industrial waste on a big scale. This advanced system takes used oil sludge and turns it into useful products like fuel oil and carbon black, combining modern engineering with green principles. What makes this process so valuable is that it keeps tons of hazardous material out of landfills while creating renewable energy sources for power generation and heating systems. For facilities dealing with large volumes of oily waste, this kind of pyrolysis setup offers real-world solutions to both waste disposal problems and energy needs simultaneously. The environmental impact alone justifies the investment for many manufacturing plants looking to reduce their ecological footprint.

New Tire/Rubber Cracking Furnace

The new tire rubber cracking furnace transforms old tires into useful stuff like oil, gas, and carbon black with impressive efficiency. We're talking about a real game changer when it comes to dealing with all those tires piling up everywhere. Landfills just can't keep up with the sheer volume of tire waste anymore. What makes this furnace stand out? It takes what would otherwise be trash and turns it into valuable materials that companies actually want to buy. For manufacturers struggling with waste disposal costs, this technology offers both environmental benefits and serious bottom line improvements. The rubber industry is starting to take notice as well, since recycled materials from these furnaces compete pretty well with virgin products on price alone.

Semi-Continuous Waste Tire Recycling Plant

Semi Continuous Waste Tire Recycling Plants offer businesses a practical way to recycle tires without breaking the bank. These facilities can work with different types of tire waste and manage resources better than traditional methods. The system uses a mix of continuous and batch processing which helps recover more rubber, steel and other valuable materials from old tires. Less waste ends up in landfills and energy costs drop significantly compared to older technologies. For companies trying to stay green but still make money, these plants hit the sweet spot between environmental responsibility and operational profitability. Many operators find they can scale production up or down depending on market conditions, giving them flexibility that's hard to match with fully automated systems.

High-Quality Waste Tyre Pyrolysis Machine

The High-Quality Waste Tyre Pyrolysis Machine is engineered for durability and superior performance, ensuring efficient conversion of waste tires into alternative fuels. This machine not only supports sustainable development goals but also offers an attractive alternative to traditional fossil fuels, reducing environmental impact and promoting cleaner energy consumption.

Fully Continuous Pyrolysis Reactors

Fully Continuous Pyrolysis Reactors are at the forefront of waste processing technology, offering seamless operations for optimal resource recovery. These reactors are equipped with various innovations that ensure maximum output, while complying with stringent environmental regulations. They exemplify the future of waste management, balancing high performance with eco-friendly practices.

Benefits and Challenges in Resource Recovery

Economic and Environmental Advantages

Getting value back from waste processing brings real benefits for both wallets and the planet. When companies turn trash into things we actually need like electricity, chemical compounds, or building materials, they cut down on what it costs to throw stuff away while making money off the new products too. The whole process tends to create work opportunities at recycling centers and helps build markets where people want to buy secondhand goods. From an environmental standpoint, good waste handling means less garbage ends up in landfills. That's important because when waste stays out of those giant pits, there's less pollution overall and we save precious natural resources that would otherwise get used up. Industries that focus on recovering resources instead of just tossing everything are paving the way toward sustainability. They generate less waste generally and leave behind a smaller mark on our environment than traditional methods do.

Addressing Operational Challenges

Tackling operational problems matters a lot when it comes to getting resources back from waste processing. Systems that crack materials apart using heat or chemicals run into all sorts of headaches regularly. Equipment tends to fail unexpectedly, maintenance becomes a constant hassle, and the quality of incoming waste varies wildly day to day. These issues really mess up the whole operation if not handled properly. Good old fashioned preventive maintenance works wonders here, along with better controls on the production line and smarter ways to handle different types of feedstock coming in. Companies also find value in training their workers thoroughly so they know what signs to watch for. Putting money into sensors and other monitoring gear pays off too, since these tools catch small problems before they turn into big disasters. All this combined makes the whole recycling process work better and faster in the long run.

Hot News

Hot News