QUALITY PRODUCT

The annual processing capacity of a single unit is 20,000 tons, which easily passes the approval of the project and environmental assessment, and is strongly supported by domestic policies.

AOTEWEI's Continuous Cracking Equipment is the ultimate choice for refiners seeking sustainability and efficiency. Our systems excel in reducing energy waste and improving oil quality.

In today’s world where people are increasingly becoming aware about the environment, industrial operations should aim at reducing their impacts on the same. This is a duty that AOTEWEI understands and has hence incorporated it in designing its Continuous Cracking Equipment. Through optimization of the cracking process, productivity is enhanced by these machines to minimize harmful releases.

AOTEWEI equipment is designed efficiently to reduce waste and lowering the level of greenhouse gases making it environmentally friendly for refineries. The advanced thermal recuperator in this system further adds up to energy savings thus reducing carbon footprint during refining.

Refiners who choose AOTEWEI Continuous Cracking Equipment show a commitment towards environmental stewardship while still attaining business goals. Facilities using AOTEWEI technology runs clean and smooth, setting new benchmarks for sustainable petrochemical production.

Waste tires pose a major environmental challenge and opportunity. This is where AOTEWEI’s Continuous Cracking Equipment comes in; it helps in transforming the waste into valuable crude oil, thus showing that the company has always been committed to sustainable and innovative measures.

Further, by using advanced cracking technologies, AOTEWEI’s equipment enables reuse of oil, gas and other components from waste tires. Not only does this process alleviate landfills but it also recovers important resources which can be further refined into usable energy. Ability to continuously turn waste into crude oil guarantees availability of refining feedstock making it an environmentally friendly and economically viable choice for refiners.

Furthermore, with AOTEWEI’s equipment providing precision and control, the quality of produced crude oil remains consistent hence making it suitable for further refining processes. Therefore, this capability enhances sustainability of tire disposal as well as boosts development of a circular economy that converts waste into precious products.

The refining industry always seeks for innovative ways to improve efficiency and productivity. A game-changer in this regard is the AOTEWEI Continuous Cracking Equipment, whose performance and reliability are unsurpassed. With tolerances designed into them at precision engineering levels, these equipment have reduced downtimes to the minimum while maintaining their operational integrity which makes them indispensable assets in the present day refineries.

One of the critical benefits of using AOTEWEI’s equipment is that it can operate nonstop without sacrificing either quality or safety. This not only results in increased production rates but also significantly decreases energy usage and operating expenses. Superior heating system and accurate temperature control facilitate optimal cracking conditions leading to higher yields and improved oil quality.

Investment in AOTEWEI Continuous Cracking Equipment is a wise decision for refineries that wish to remain competitive in the energy market. Through advanced technology and commitment towards excellence, AOTEWEI helps refiners meet efficiency objectives all over the world.

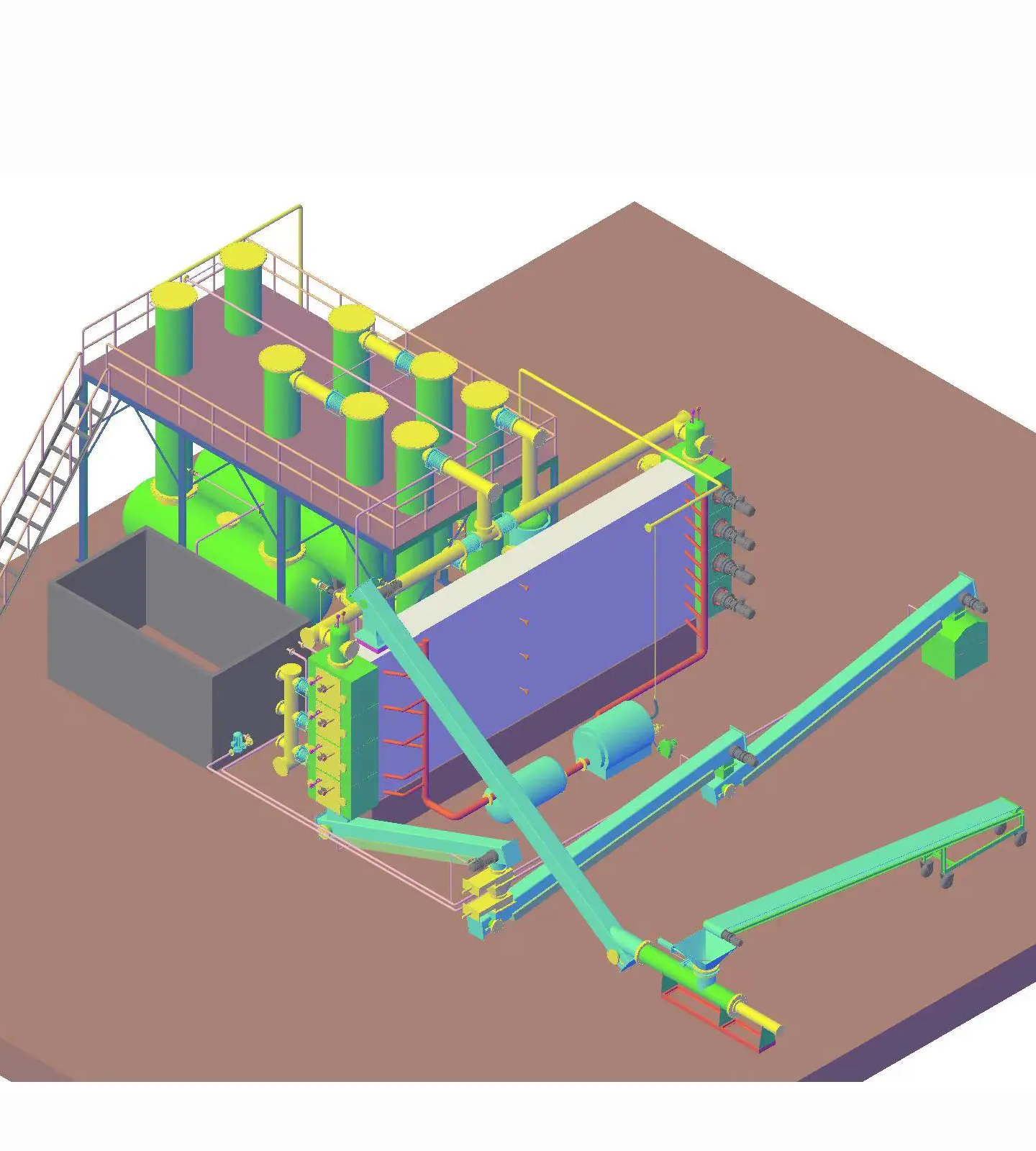

AOTEWEI is a technology leader, and this can be seen in its continuous cracking equipment that has revolutionized tire to oil conversion. The plant combines modern cracking techniques and stands out as the best way to process waste tires.

The device has highly developed heating and distillation systems to optimize tire material decomposition so as to obtain high yields of good quality crude oil. In addition, it is capable of adjusting cracks through real-time monitoring that can recognize and adjust automatically which makes it adaptable to various types of inputs. This feature allows resource recovery which results in several economic benefits for investors in the waste-to-oil industry.

Moreover, automatic operation of Aotewei’s continuous cracking equipment reduces human intervention while mitigating operational risks at the same time as a result enhancing safety at work place. Automation such as this results not only in better control and more efficient operations but also brings out Aotewei’s advancement towards innovative sustainability practices which will facilitate easier switch over for green businesses involved in refining to sustainable refineries.

In addition, such machinery from Aotewei ensures uniformity of produced crude oil facilitating future processing even though further refining processes have been carried out on it. This capability not only enhances the sustainability of the waste tire disposal process but also supports a circular economy where wastes are upcycled into value-added goods.

Shangqiu AOTEWEI is a research and development, manufacturing, sales, comprehensive technical services, import and export trade in one of the machinery equipment company. The company's main equipment, mainly divided into two categories:

Organic solid waste cracking oil refining equipment treats a wide range of raw materials: waste tires, waste plastics, aluminum-plastic, aluminum foil, domestic waste and other organic solid waste as well as oily sludge, paint slag, chemical waste and other hazardous waste for reduction, harmless, resource recycling.Waste oil distillation equipment: Raw materials can be: waste oil, waste diesel oil, mechanical oil, hydraulic oil, heat transfer oil, transformer oil, gear oil, waste oil residue, bilge oil, semi-flow waste oil, so that waste into economic renewable energy.

The annual processing capacity of a single unit is 20,000 tons, which easily passes the approval of the project and environmental assessment, and is strongly supported by domestic policies.

Continuous production can reach more than 100 days, higher pyrolysis efficiency and more accurate intelligent automatic control.

Good sealing, safe and reliable, stable operation, higher production efficiency, safer production.

Clean and environmental protection, online monitoring standards, all emissions are in line with EEA, EPA and other international standards.

Honest business with competitive price and professional service on export process.

We consider honest as the life of our company, we can tell you the contact information of our some other clients for you to check our credit. Besides, there is trade assurance from Alibaba, your order and money will be well guaranteed.

Sure,welcome to you visit our factory at any time.

Within 15-35 days after we confirm you requirement.

T/T, 100% L/C at sight, Western Union are all accepted if you have other payment,please contact me.

Copyright © 2025 by Shangqiu AOTEWEI environmental protection equipment Co.,LTD Privacy policy