QUALITY PRODUCT

The annual processing capacity of a single unit is 20,000 tons, which easily passes the approval of the project and environmental assessment, and is strongly supported by domestic policies.

Transform waste into treasure with AOTEWEI's cutting-edge cracking equipment. Ideal for tire recycling, plastic conversion & more. Experience unmatched efficiency, environmental compliance, and a clear ROI. Explore now!

End-of-life tires remain a mammoth problem worldwide. In view of the huge tire dumps, AOTEWEI comes in with its End-of-Life Tire Pyrolysis Process that is revolutionary and offers the effective way how to deal with waste accumulation in the form of used tires.

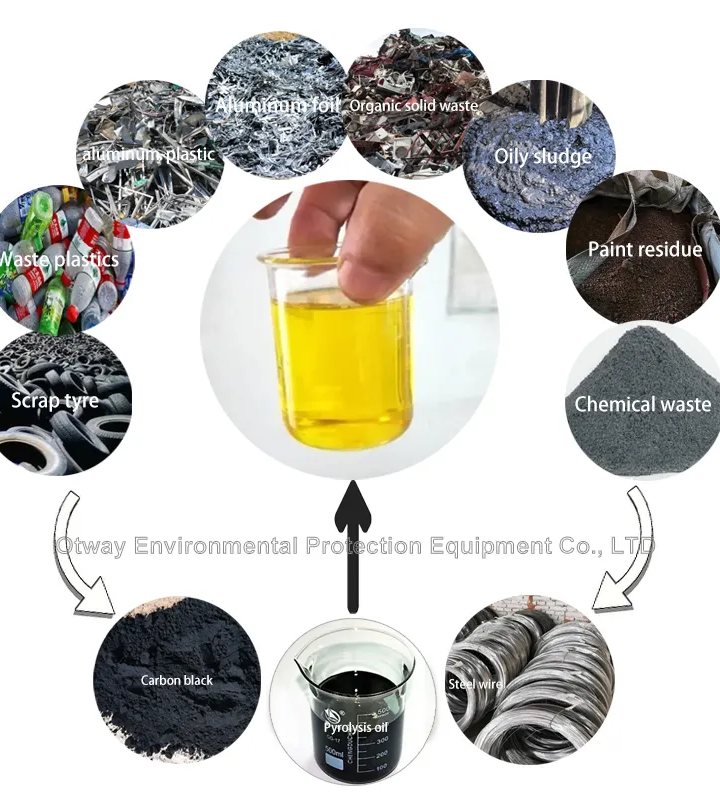

This equipment splits down the tire materials by heat under certain circumstances to get beneficial prod-ucts such as pyrolysis oil, steel and carbon black. This hydrocarbon-rich oil can be upgraded into fuel or used for various industrial purposes and its steel reinforcements are reused while carbon black can be employed as a feedstock for manufacture or an energy source.

AOTEWEI’s technology reduces the amount of space needed for landfills by changing end-of-life tyres into reusable substances instead of causing harmful effects on nature resulting from massive piles of rubber. Moreover, there is a circularity in recovering resources and returning them again to productive use through this process.

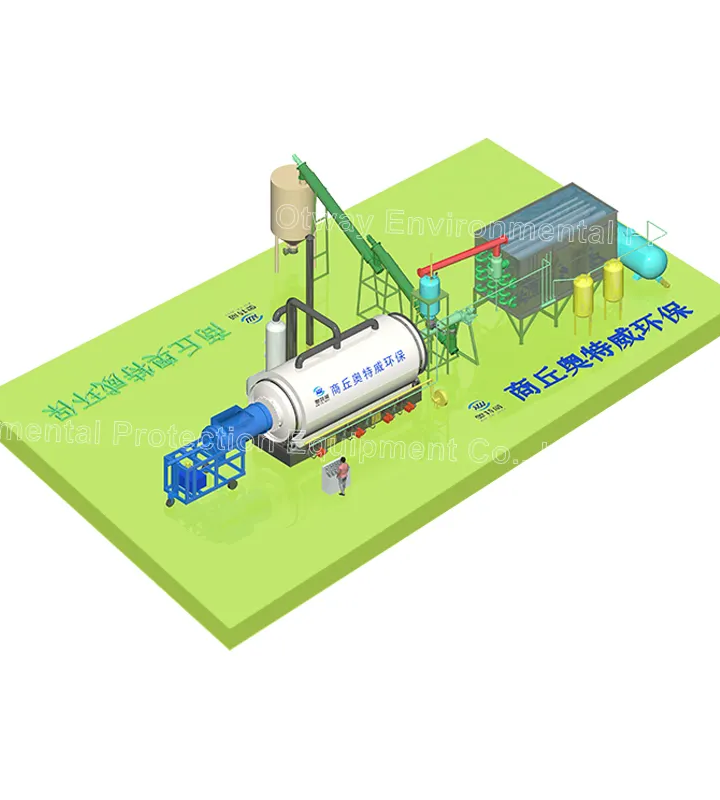

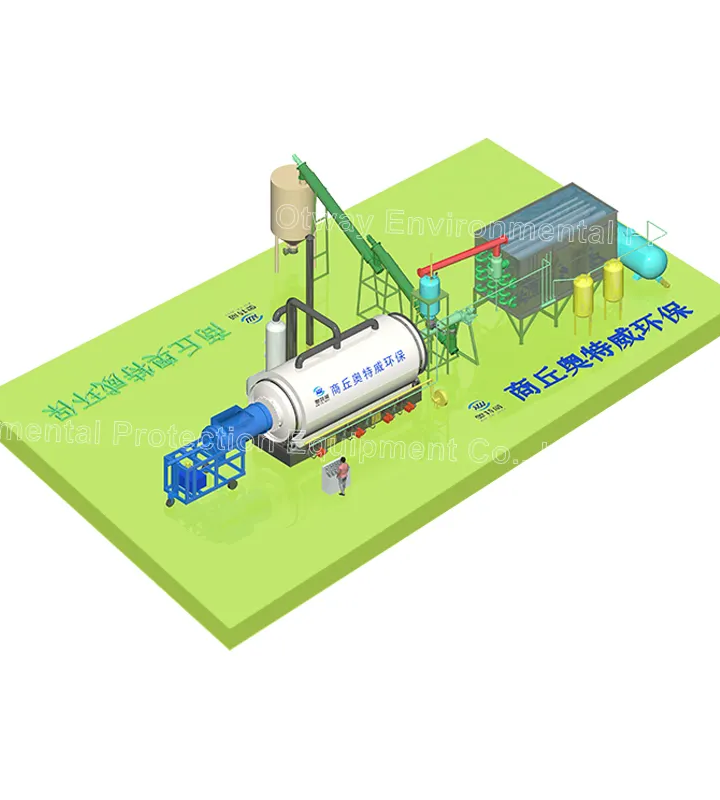

AOTEWEI high efficiency waste tire cracking unit is the yardstick of waste tire management, whose aim is resource recovery maximization and minimizing environmental footprints. For example, this unit with a state-of-the-art technology enables to effectively convert end-of-life tires into valuable products that can be reintegrated into the economy.

The essence of AOTEWEI’s technology lies in its capability to process whole tires without prior shredding or sorting. This method saves time and costs, thereby improving overall efficiency of waste tire cracking process. A thermal decomposition process is used for the tire materials resulting in pyrolysis oil, combustible gases as well as solid residues which have practical applications.

Moreover, minimal environmental impact comes through the operation of AOTEWEI’s High Efficiency Waste Tire Cracking Unit. During the process gases generated by it are captured and utilized within a closed loop system curbing emissions and recovering energy for use back in-house. For businesses and governments that want to achieve sustainability goals, this makes AOTEWEI’s technology ideal solution both economically viable as well as ethically sound.

When it comes to refining processes, AOTEWEI’s Cracking Equipment is an important player rising up in a bid to unlock better efficiency and performance. This machine has been designed with great care so that operators can get the best out of their refineries by boosting overall operational efficiency, minimising downtime and maximising production levels.

The first notable feature about the Cracking Equipment brand from Aotewei is its energy conserving design. The company uses modern heating technologies as well as accurate thermal control systems on these machines to optimize on energy consumption translating into huge cost savings for refiners while maintaining quality and throughput. The ability to function at optimal rates irrespective of prevailing circumstances demonstrates AOTEWE’ commitment in terms of innovation and excellence.

In addition, the user-friendly interface系统和自动化控制系统 used in operating this cracking equipment makes operation easy hence focusing more on other crucial departments within the refinery. With tremendous robustness and productivity, AOTEWEI is also preparing ground for worldwide efficient and sustainable refractions.

The world is grappling with the problem of end-of-life tires. This challenge has been effectively answered by AOTEWEI through its novel “end-of life-pyrolysis process.” It has provided an efficient and sustainable means of dealing with stockpiled waste tires.

This results in pyrolysis oil, steel and carbon black which are valuable products that come from the decomposition of tire components via controlled conditions using their equipment. The hydrocarbon-rich oil can be converted into more fuel or used as a feedstock for other industrial applications while steel reinforcements are recycled and carbon black can find use in manufacturing or as energy.

AOTEWEI’s technology converts end-of-life tires into reusable materials thereby significantly reducing landfill space obligations and also avoiding adverse impacts of tire dumps on the environment. Similarly, the process contributes to circular economies by recovering resources back into production cycles. As a result, it becomes a sustainability champion and resource efficiency promoter through such innovation as the End-of-Life Tire Pyrolysis Process.

Shangqiu AOTEWEI is a research and development, manufacturing, sales, comprehensive technical services, import and export trade in one of the machinery equipment company. The company's main equipment, mainly divided into two categories:

Organic solid waste cracking oil refining equipment treats a wide range of raw materials: waste tires, waste plastics, aluminum-plastic, aluminum foil, domestic waste and other organic solid waste as well as oily sludge, paint slag, chemical waste and other hazardous waste for reduction, harmless, resource recycling.Waste oil distillation equipment: Raw materials can be: waste oil, waste diesel oil, mechanical oil, hydraulic oil, heat transfer oil, transformer oil, gear oil, waste oil residue, bilge oil, semi-flow waste oil, so that waste into economic renewable energy.

The annual processing capacity of a single unit is 20,000 tons, which easily passes the approval of the project and environmental assessment, and is strongly supported by domestic policies.

Continuous production can reach more than 100 days, higher pyrolysis efficiency and more accurate intelligent automatic control.

Good sealing, safe and reliable, stable operation, higher production efficiency, safer production.

Clean and environmental protection, online monitoring standards, all emissions are in line with EEA, EPA and other international standards.

Within 15-35 days after we confirm you requirement.

Absolutely, upon request, we can provide a comprehensive technical specification sheet outlining dimensions, capacity, power requirements, materials used, and safety features.

Our equipment is designed to exceed industry standards with high efficiency rates and optimized output. We continuously innovate to ensure our products offer competitive performance.

Copyright © 2025 by Shangqiu AOTEWEI environmental protection equipment Co.,LTD Privacy policy