QUALITY PRODUCT

The annual processing capacity of a single unit is 20,000 tons, which easily passes the approval of the project and environmental assessment, and is strongly supported by domestic policies.

Experience superior crude oil distillation with AOTEWEI. Our innovative solutions offer enhanced efficiency, safety, and environmental sustainability, elevating your distillation process to new heights.

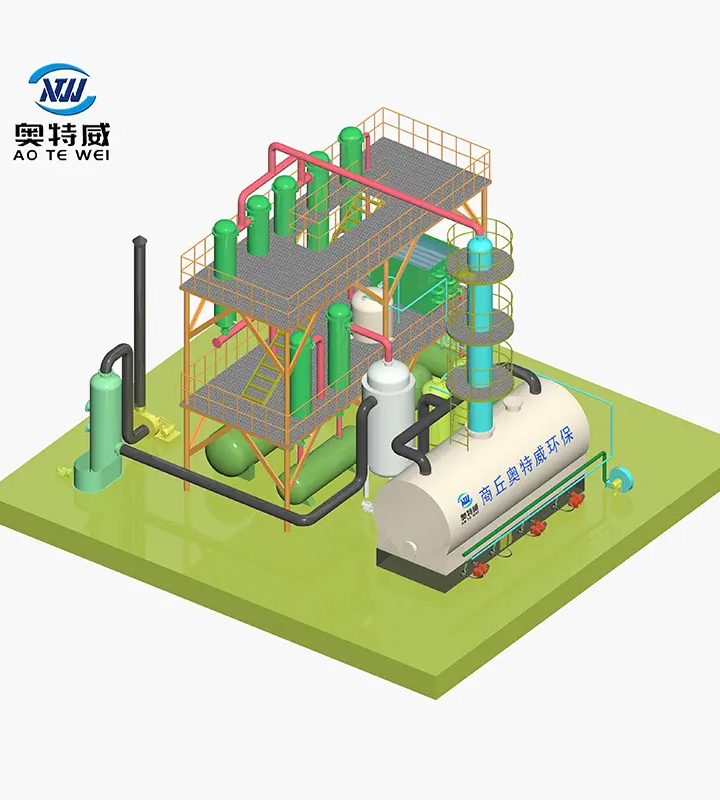

AOTEWEI’s semi-continuous cracking solution is an innovation aimed at simplifying the whole process of changing waste to oil. This method saves on operational costs and labor while maintaining quality oil output hence it is a convenient option for those companies which are aiming to achieve optimal productivity.

In this case, a semi- continuous process involves loading that happens only once in four to five days, which is crucial in cutting down interruptions during operations and minimizing frequent material handling. This approach reduces human error chances as well as labor needs thus ensuring consistent nonstop production cycle.

To make this system even better, AOTEWEI has made it have condenser cooling systems that effectively cools the expelled oil resulting in higher yields and improved oil quality. The design also considers ease of maintenance with easily accessible points for cleaning by users so as not to have too much downtime. In its thoughtful engineering, provision of technologically advanced but cost effective end user friendly solutions has been the focus of the company.

At AOTEWEI, ensuring safety is equally important as guaranteeing efficiency which is achieved through employment of modern fabrication technologies. Among these are automatic submerged arc welding, ultrasonic non-destructive testing and advanced manual and automatic safety systems. They are essential for maintaining the integrity and performance of cracking equipment.

Automatic submerged arc welding ensures strong and accurate joining of materials to enhance the durability and long life span of AOTEWEI’s devices. In combination with ultrasonic non-destructive testing, these methods enable thorough inspection while not disturbing the equipment’s structural integrity. This makes it possible to conduct comprehensive inspections that guarantee no faults in the machines hence they operate safely and reliably.

Furthermore, AOTEWEI has invested in both manual and automated security systems whose main purpose is to care for the health of people working on site as well as protect our environment. These new generation solutions control operation parameters setting automatically when necessary or shutting down if predetermined security limits have been ruptured making again AOTEWEI for being a safety company first.

To improve its effectiveness further, AOTEWEI also manufactured it with condenser cooling mechanisms that cool out all oil extracted from it thoroughly hence higher yields and better quality oil This configuration also considers ease of maintenance by providing regular access points that can easily be cleaned by users without requiring much time-off work These thoughtful engineering decisions reflect how devoted AOTEWEI Company is to providing its clients with cost effective technologically progressive measures that are user friendly too.

The main goal of crude oil distillation is to obtain top product purity while ensuring flexibility in the refining output. The need to satisfy these conditions prompted AOTEWEI to engineer its distillation columns with great meticulousness. These are multi-stage fractionation systems that split crude into discrete fractions having distinct boiling points, leading to ultimate product streams with highest levels of purity.

Apart from that, AOTEWEI’s distillation technology covers all types of crudes beginning from light sweet crudes up to heavy sour crudes making evident its ability to respond effectively on different refining challenges. This means that it can be used for a variety of petrochemical products which will enable them meet the changing needs of both domestic and international markets.

To sum up, AOTEWEI's crude oil distillation processes represent accuracy and adaptability thus helping refineries get high quality products as they remain flexible in the volatile market environment.

AOTEWEI’s waste oil distillation plant signifies dedication to conserving resources and improving efficiency by converting used oils into energy sources of high value. In this respect, AOTEWEI follows its mission of offering environmentally friendly solutions which are not like the old ways of getting rid of rubbish.

This Waste Oil Distillation Plant processes waste oils through advanced distillation techniques that enable them to be turned into top quality oils for power generation or heating purposes. This in turn reduces discharges related pollution as they do not need to be disposed off and also minimizes health risks associated with accumulation of waste oil.

For example, it is important to mention that the facility has very strong measures for quality control which make sure the output is uniform and pure. This will therefore raise the market position for AOTEWEI besides building consumer trust on their dependable carbon neutral energy supplies. If a company were to purchase AOTEWEI’s Waste Oil Distillation Plant, this would give it an opportunity to benefit from an ever growing demand for green power as well as opting for a cleaner earth.

Shangqiu AOTEWEI is a research and development, manufacturing, sales, comprehensive technical services, import and export trade in one of the machinery equipment company. The company's main equipment, mainly divided into two categories:

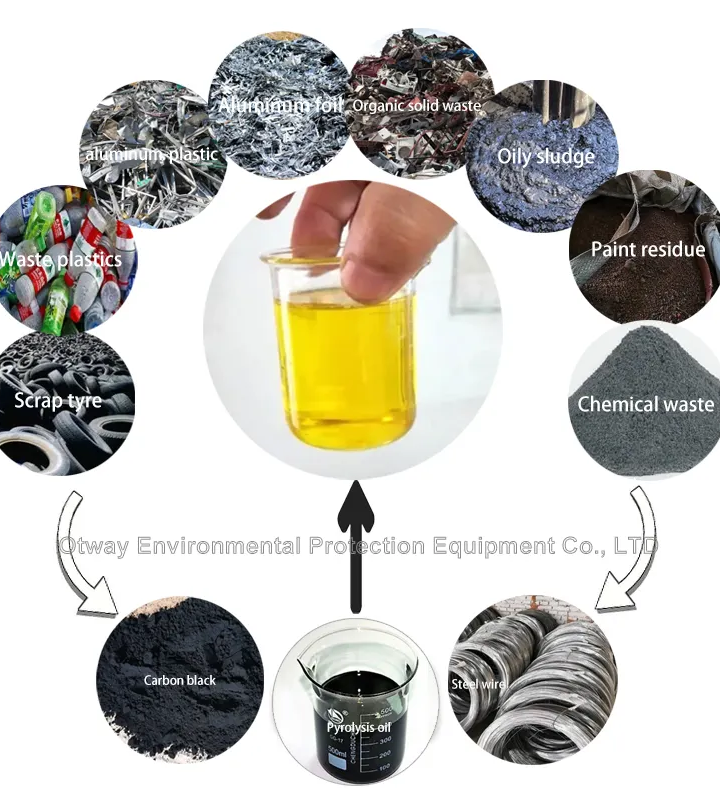

Organic solid waste cracking oil refining equipment treats a wide range of raw materials: waste tires, waste plastics, aluminum-plastic, aluminum foil, domestic waste and other organic solid waste as well as oily sludge, paint slag, chemical waste and other hazardous waste for reduction, harmless, resource recycling.Waste oil distillation equipment: Raw materials can be: waste oil, waste diesel oil, mechanical oil, hydraulic oil, heat transfer oil, transformer oil, gear oil, waste oil residue, bilge oil, semi-flow waste oil, so that waste into economic renewable energy.

The annual processing capacity of a single unit is 20,000 tons, which easily passes the approval of the project and environmental assessment, and is strongly supported by domestic policies.

Continuous production can reach more than 100 days, higher pyrolysis efficiency and more accurate intelligent automatic control.

Good sealing, safe and reliable, stable operation, higher production efficiency, safer production.

Clean and environmental protection, online monitoring standards, all emissions are in line with EEA, EPA and other international standards.

Yes, our units are designed to handle a wide range of crude oil types, including heavy and light crudes.

Yes, our units are fully compliant with all relevant international environmental standards and regulations.

Regular maintenance is required, including inspections, cleaning, and replacement of worn parts, as detailed in the maintenance manual.

T/T, 100% L/C at sight, Western Union are all accepted if you have other payment,please contact me.

Honest business with competitive price and professional service on export process.

Copyright © 2025 by Shangqiu AOTEWEI environmental protection equipment Co.,LTD Privacy policy