The Role of Waste Plastic Oil Refining in the Circular Economy

Closing Material Loops Through Plastic-to-Oil Conversion

Turning waste plastic into oil through refining helps move us toward a circular economy model where we don't just throw stuff away after one use. The process basically melts down those hard to recycle plastics and turns them back into something useful like synthetic crude oil, which cuts down our reliance on brand new fossil fuels. Most pyrolysis systems can get around 70% of the plastic material converted into usable hydrocarbons, so instead of ending up in landfills or being burned, these materials find another life. What comes out of this process works great as raw material for making diesel fuel and various petrochemical products. This approach keeps resources in circulation longer rather than letting them disappear as waste, which makes sense both environmentally and economically when looking at long term sustainability.

How Circular Economy Integration in Plastic Waste Management Drives Regional Sustainability

Local areas that implement plastic to fuel conversion systems typically see around 30 to maybe even 50 percent reduction in what they spend expanding landfills, plus they get their own local source of energy. When cities combine regular trash pickup with those small scale refining operations, they end up with two good things happening at once fewer pollutants going into ecosystems and generating power right where it's needed. Take a look at what's happening across parts of Southeast Asia these days. New refining centers are popping up all over the place, showing how bringing together different aspects of waste management can make regions more self sufficient while also cutting down on the need to import traditional fossil fuels from other countries.

Rising Plastic Waste and the Emergence of Refining Hubs

The world now produces over 400 million metric tons of plastic waste every year, which has led to the emergence of recycling facilities right next to major cities and factories. In many coastal areas across developing countries, local plants are turning ocean trash into cleaner burning fuel for ships. Meanwhile, wealthier nations tend to break down old packaging materials into naphtha used in making various chemicals. These geographic concentrations make transportation easier and help create job opportunities for workers with specific skills in recycling technology. As a result, we're seeing faster progress toward true circular economy models where nothing goes to waste.

Core Waste Plastic Oil Refining Technologies: Pyrolysis, Gasification, and Beyond

Overview of Plastic-to-Oil Conversion Technologies: Pyrolysis, Gasification, and Hydrothermal Liquefaction

Three primary thermochemical methods dominate waste plastic oil refining:

-

Pyrolysis: Thermal decomposition without oxygen (350–900°C), yielding 60–80% liquid hydrocarbons

-

Gasification: Partial oxidation (700–1,200°C) producing syngas (CO/H₂) for power or chemicals

-

Hydrothermal Liquefaction: Water-based processing (300–400°C) suitable for mixed plastic streams

Pyrolysis achieves up to 85% carbon recovery efficiency for polyethylene and polypropylene, outperforming mechanical recycling for degraded plastics.

Why Pyrolysis Leads in Waste Plastic Oil Refining

Pyrolysis holds 40.6% of the plastic-to-fuel technology market due to lower energy demands (40% less than gasification), direct production of drop-in fuels, and compatibility with mixed plastics–excluding PVC and PET. Advances like zeolite catalysts boost gasoline-range hydrocarbon yields to 78%, making the process economically viable even at $50/barrel crude prices.

Comparing Efficiency and Output of Pyrolysis and Gasification Methods

| Metric | Pyrolysis | Gasification |

| Oil Yield | 65–85% | 0% (syngas only) |

| Energy Input (kWh/kg) | 1.2–1.8 | 2.4–3.6 |

| Primary Output | Synthetic crude | Syngas (CO + Hâ‚‚) |

| Commercial Adoption | 420+ plants operational | 27 pilot facilities |

While gasification enables syngas conversion to methanol for industrial use, pyrolysis remains the preferred route for circular economy hubs needing liquid transportation fuels.

Catalytic Conversion Innovations Enhancing Chemical Recycling

Advanced catalysts now achieve 93% polyolefin conversion in fluidized bed reactors and remove 99% of chlorine from PVC-containing feeds. Ni-Fe/CaO bifunctional catalysts reduce coke formation by 62% while capturing CO₂–key for meeting EU sustainability standards. These innovations improve fuel quality, with cetane numbers exceeding 51 for diesel-range outputs.

Emissions and Limitations of Thermochemical Refining: Addressing Environmental Concerns

The latest emission control systems bring down dioxin levels to below 0.1 ng TEQ per cubic meter, which is a dramatic improvement from the 50 ng found in open burning scenarios. These systems also slash particulate matter by nearly all thanks to electrostatic precipitators working their magic, while biochar applications manage to lock away around a third of carbon dioxide emissions. On the flip side though, about one out of every eight pyrolysis oils still carries traces of heavy metals that need special treatment called hydrotreatment. This extra step adds between eighteen and twenty-five dollars per ton to processing expenses. Facilities across Southeast Asia have been keeping tabs on their emissions continuously, and as a result they're hitting about ninety percent compliance rates according to recent UNEP reports from last year.

From Plastic Waste to Synthetic Crude Oil: The Conversion Process

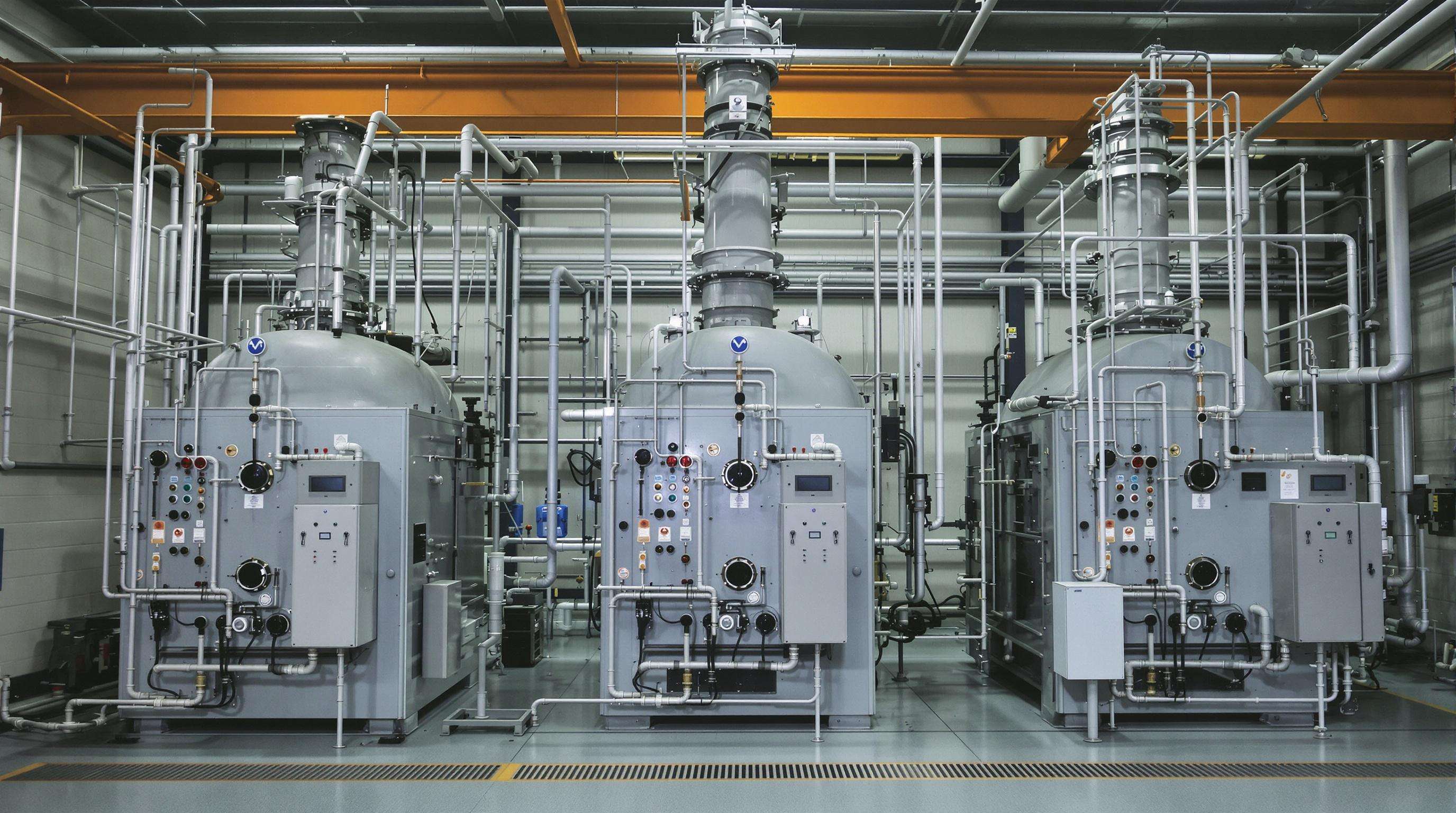

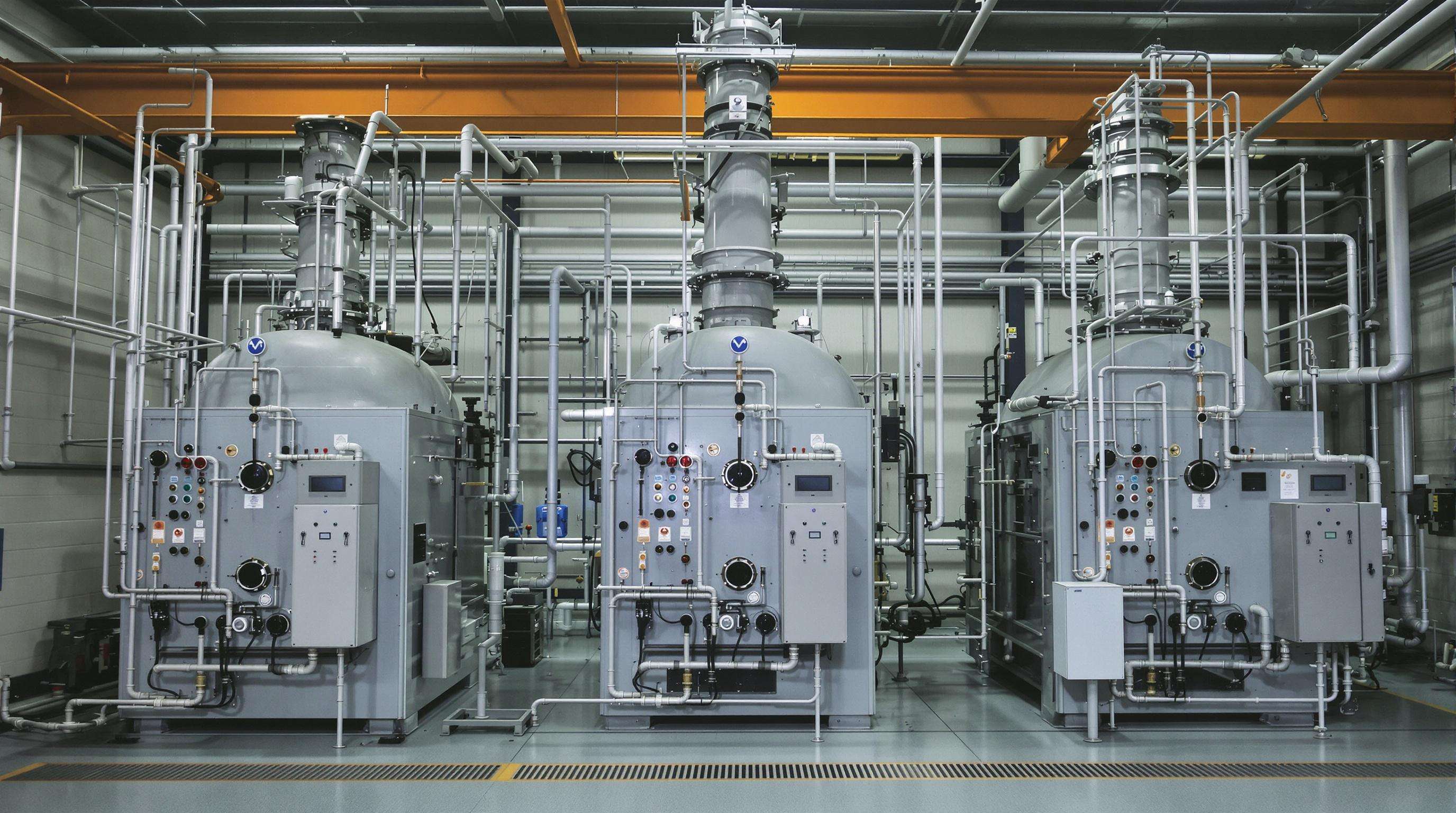

Step-by-Step Process of Converting Waste Plastics to Oil Using Pyrolysis

The pyrolysis process turns plastic waste into synthetic crude oil by breaking down materials through heat in sealed reactors without oxygen present. First comes the sorting stage where different types of plastics get shredded down to small pieces measuring around 2 to 10 millimeters across. After that comes drying to remove any remaining moisture from the material. When we talk about slow pyrolysis, it typically runs at temperatures between 400 and 550 degrees Celsius for periods lasting anywhere from half an hour to almost two hours straight, producing roughly 74 percent oil. Fast pyrolysis works differently though, reaching temperatures above 700 degrees within just seconds which actually boosts the liquid yield to about 85 percent instead. The vapor produced during this gets cooled down and turned into usable fuel oil. What remains after processing includes about 20 percent char and approximately 6 percent syngas, both of which can be put back into the system as additional energy sources. More sophisticated setups now include real time monitoring equipment that helps maintain optimal conditions and ensures better quality outputs consistently.

Feedstock Requirements for Efficient Pyrolysis Oil Production

For pyrolysis to work well, the feedstock needs to contain plenty of polyolefins like polyethylene (PE) and polypropylene (PP), which account for around 60 to 70 percent of all plastic waste worldwide. Keeping moisture levels under 10% is pretty important too, while PVC and PET should stay below 1% to avoid those nasty corrosive emissions during processing. When blends include up to 15% polystyrene, operators typically get somewhere between 680 and 720 liters of oil from each ton processed. Having consistent material composition really helps boost catalytic efficiency. Fortunately, new technology has changed things quite a bit lately. AI driven hyperspectral sorting systems are making it much easier to separate different polymers accurately and remove contaminants that would otherwise ruin the whole batch.

Case Study: Successful Plastic-to-Fuel Conversion in Southeast Asian Circular Economy Hubs

Located along Indonesia's Java Economic Corridor, there's this facility that handles around 35 metric tons of plastic waste each day, turning it into diesel that meets ASTM standards. They've got these modular pyrolysis units running the show, churning out about 12 thousand liters of transport fuel daily for nearby industries. This operation keeps roughly 94 percent of all that plastic out of landfills too. The company works closely with local waste collectors and has implemented some kind of blockchain system to track their environmental impact metrics. Their investment pays off pretty quickly actually - they see returns within just over a year. Since starting operations back in 2022, the facility has managed to cut down marine plastic pollution by nearly 40%, which is quite impressive considering how much plastic ends up in our oceans otherwise.

Innovations Advancing Waste Plastic Oil Refining Efficiency

Improving Yield and Purity in Waste Plastic Oil Refining

Hyperspectral imaging now achieves 98% polymer separation accuracy, improving feedstock purity. Transition metal-doped zeolites increase oil yields by 25–35% and reduce chlorine content below 0.5%. Optimized reactors operating at 500°C with 60-minute residence times achieve 82% liquid hydrocarbon recovery–14% above five-year averages.

Role of Catalytic Methods in Producing High-Quality Synthetic Crude and Fuels

Catalytic cracking upgrades pyrolysis vapors into diesel that meets EN 590 standards without further refining. Modified steam reforming recovers 92% of hydrogen from plastic polymers, enabling internal reuse in refinery operations. Improved catalyst durability–exceeding 8,000 operating hours–is projected to reduce synthetic crude production costs by 40% by 2030.

Emerging Advanced Conversion Technologies for Resource Recovery

Microwave-assisted pyrolysis targets molecular bonds directly, achieving 98% energy efficiency and reducing process temperatures by 200°C. Solvolysis recovers intact monomers from multi-layer packaging, with pilot plants demonstrating 97% recovery for PET and polyolefins. Gasification-plasma hybrids convert 99.9% of plastics into syngas while eliminating dioxins via three-stage thermal oxidation.

AI and Automation Trends in Sustainable Chemical Processing of Plastic Waste

Machine learning models predict optimal pyrolysis parameters for mixed plastics with 2% accuracy, cutting trial runs by 75%. Raman spectroscopy-powered quality control adjusts reactor conditions in real time to maintain oil viscosity within ±0.5 cSt. Digital twin systems in European refineries have boosted annual throughput by 22% through predictive maintenance and continuous optimization.

Economic and Environmental Impact of Plastic-to-Fuel Technology

Assessing the environmental footprint of waste plastic oil refining

The process of turning waste plastic into oil cuts down on landfill space by roughly 85 to 90 percent over regular trash disposal methods. Studies looking at the full life cycle of materials indicate that these pyrolysis systems produce around 30 percent less greenhouse gases than pulling oil out of the ground, provided the energy from the process gets properly captured. There's still a challenge though with handling dangerous leftovers such as dioxins and various heavy metals. Good pollution control measures are absolutely necessary if we want to meet those circular economy goals that so many industries talk about nowadays.

Economic viability of plastic waste to diesel conversion in emerging markets

Profitability depends on feedstock access and scalable infrastructure. In Southeast Asia, pyrolysis plants achieve payback in 4–7 years, with synthetic diesel production costing $0.40–$0.60 per liter. Lower labor costs and government incentives improve feasibility, though fluctuating oil prices and inconsistent waste quality pose risks to long-term stability.

Scaling waste plastic oil refining for sustainable circular economy integration

Scaling success relies on hybrid financing–combining public grants with private investment. Modular refineries processing 20–50 tons/day reduce capital costs by 40% compared to traditional systems. Regional clusters that integrate material recovery with refining achieve 15–25% higher resource efficiency, establishing closed-loop systems for non-recyclable plastics.

Frequently Asked Questions

What is waste plastic oil refining?

Waste plastic oil refining is a process that converts waste plastics into synthetic crude oil or other useful chemicals, reducing reliance on new fossil fuels and contributing to a circular economy.

How does pyrolysis work in plastic-to-oil conversion?

Pyrolysis involves heating plastic waste in the absence of oxygen to break it down into liquid hydrocarbons, which can be used as synthetic crude oil or processed into fuels like diesel.

What are the environmental benefits of plastic-to-fuel technology?

This technology reduces landfill waste, cuts greenhouse gas emissions by about 30% compared to traditional oil extraction, and helps manage marine plastic pollution.

What are the challenges in waste plastic oil refining?

Some challenges include handling emissions such as dioxins and heavy metals, ensuring consistent waste feedstock, and managing the costs associated with advanced refining technologies.

Is plastic-to-fuel conversion economically viable?

Yes, particularly in regions with lower labor costs and government incentives. Plants in Southeast Asia achieve payback within 4 to 7 years, with production costs for synthetic diesel ranging from $0.40 to $0.60 per liter.

Hot News

Hot News