What are the common problems of waste tire oil refining equipment?

How to deal with it?

In the entry of waste tire oil refining project, the purchase of waste tire oil refining equipment, people are often most concerned about the problem of oil yield, profit, safety and environmental protection. Today, let Dongying Xiaobian start from the three common problems of waste tire refining equipment to tell you about the concerns and interest points of a wide range of customers in the market.

First, the oil yield problem

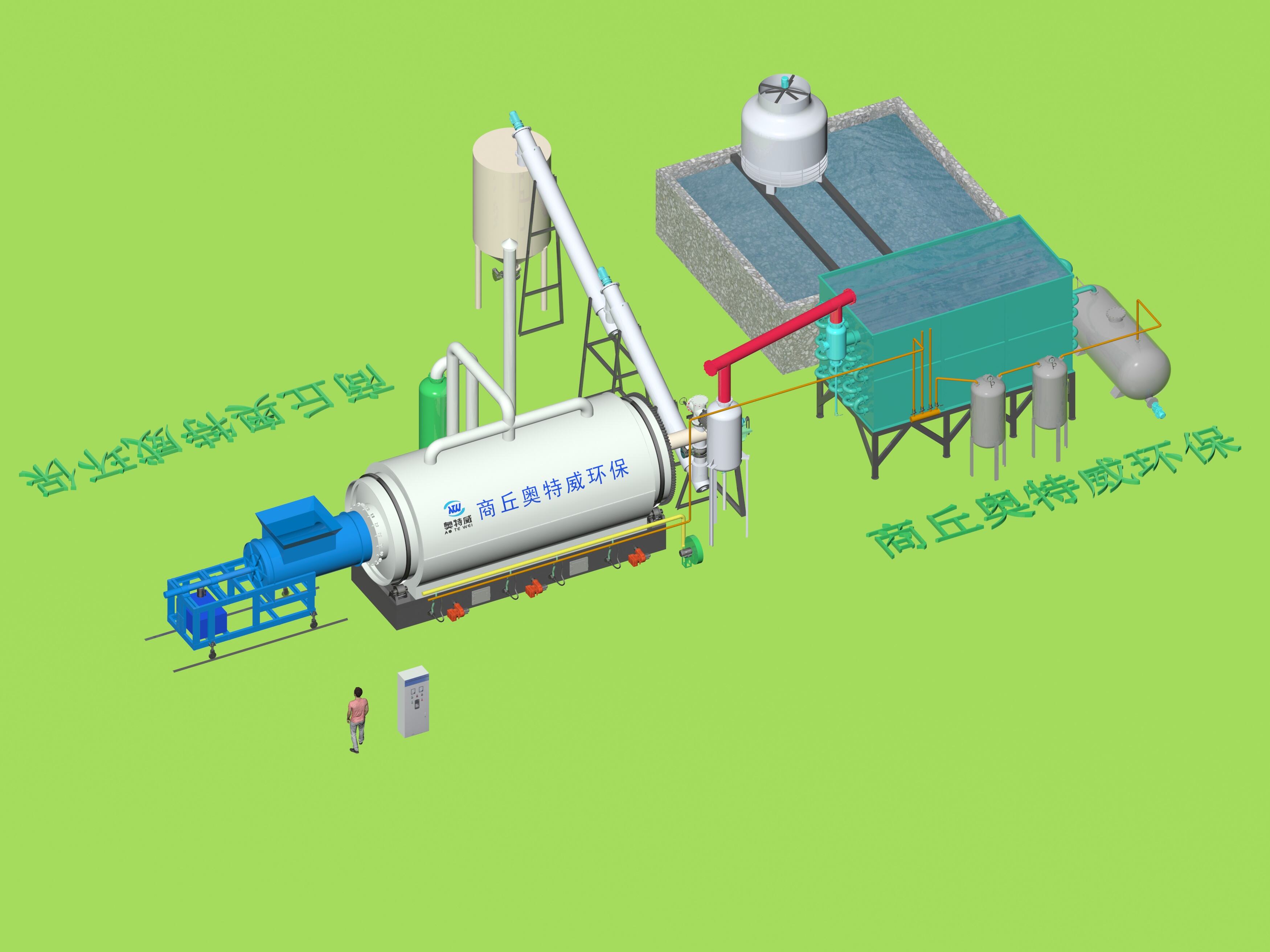

There are no more than two points that play a decisive role in the oil yield of waste tires, one is the raw material and the other is the equipment. The oil yield of different raw materials is different, such as the oil yield of waste tires such as large truck tires, engineering tires, and small steel tires is relatively high, and the oil yield of bicycle tires and electric motorcycle tires is less. Then from the point of view of equipment, the process, technology and quality of different manufacturers of waste tire refining equipment will affect the oil yield in the operation stage of waste tire refining equipment, whether the oil yield can be guaranteed mainly depends on the condensation link, if the temperature of the condensate water is not cool enough, the condensation area is not large enough, then the oil and gas produced by cracking can not be fully condensed, and the oil yield is naturally not enough. The condensation system designed by Dongying waste tire refining equipment manufacturer is progressive, with a total of four condensing systems (vertical condenser, oil-water separator, horizontal condenser, condensing tower), seven condensers (2 vertical condensers, 1 oil-water separator, 2 horizontal condensers, 2 condensing towers), and a total cooling area of 100 square meters. To ensure that customers can maintain stable oil yield of waste tire refining even when the site is limited.

Second, the issue of profit

The amount of profit brought by waste tire oil refining project is naturally the most concerned among the common problems of waste tire oil refining equipment. In fact, the economic profits brought by the production line are well calculated, the cost prices of raw materials, product prices, artificial water and electricity in operation are open and transparent, if you choose Dongying waste tire refining equipment, then there is a profit forecast in the feasibility report issued by Dongying for you. However, the waste tire oil refining project itself is a very dependent on the market market, greatly affected by market fluctuations, there are periods of profitmaking and flat periods every year, depending on whether the bosses have industry foresight and operational control, whether they can seize the market opportunity to wind up.

Third, safety and environmental protection issues

If the profit problem is a broad point of interest in the entry of waste tire refining equipment, then safety and environmental protection is the cornerstone of the real entry into the waste tire refining industry, because they play a top priority role in the approval of the EIA procedures, and the EIA barrier must be overcome. From the safety point of view, the waste tire oil refining equipment on the market today is generally no problem, and there are not so many safety hazards as the previous earth furnace, and manufacturers will design layers of encrypted safety prevention systems to ensure the safety of waste tire oil refining equipment. Therefore, in the purchase of waste tire refining equipment can not covet small and cheap, to visit the plant, choose the quality process clearance, labor and material enough equipment.

In addition, the operation of waste tire refining equipment must follow the operation manual, especially in the slag discharge link, can not blindly open the furnace with the color of the furnace body, do not look at the temperature measuring instrument, etc., after all, the direct contact between the oil and gas without refining and the air will flash. From the point of view of environmental protection, the environmental performance of today's continuous waste tire refining equipment is higher, because it is carried out in a completely closed environment, does not involve the link of opening the furnace door and pulling steel wire carbon black, the refinery site is much cleaner, and it is easier to pass the EIA acceptance in areas with strict environmental protection requirements.