Modern waste management challenges have driven significant innovation in recycling technologies, with pyrolysis equipment emerging as a cornerstone solution for converting various waste materials into valuable resources. The growing demand for sustainable waste processing has highlighted the importance of understanding how different feedstock materials require specialized equipment configurations. Tire waste and plastic waste present unique processing challenges that demand distinct approaches in pyrolysis equipment design and operation.

The fundamental differences between tire and plastic waste materials create distinct requirements for pyrolysis equipment specifications. Understanding these differences enables operators to optimize their processing efficiency, maximize product yields, and ensure safe operations. This comprehensive analysis explores the technical distinctions, operational considerations, and equipment modifications necessary for effective tire versus plastic pyrolysis processing.

Feedstock Material Properties and Processing Requirements

Physical Characteristics of Tire Waste

Tire waste presents unique challenges for pyrolysis equipment due to its complex composite structure. Automotive tires contain approximately 45-50% rubber polymers, 20-25% carbon black, 15-20% steel wire reinforcement, and 10-15% textile fibers. This heterogeneous composition requires pyrolysis equipment designed to handle mixed materials effectively. The presence of steel wire belts necessitates specialized feeding systems and pre-processing equipment to ensure proper material preparation.

The high density and irregular shapes of tire pieces demand robust conveying systems within the pyrolysis equipment. Tire waste typically requires size reduction to 2-5 cm chips before processing, which influences the design of feeding mechanisms. The steel content also affects heat distribution patterns, requiring pyrolysis equipment with enhanced thermal management capabilities to ensure uniform heating throughout the reactor chamber.

Temperature profiles for tire pyrolysis typically range from 350°C to 500°C, with optimal decomposition occurring around 450°C. This temperature range influences the reactor design specifications and heating system requirements for tire-specific pyrolysis equipment. The decomposition kinetics of tire rubber also create specific vapor residence time requirements that affect reactor geometry and gas handling systems.

Plastic Waste Processing Characteristics

Plastic waste materials exhibit significantly different properties that impact pyrolysis equipment design requirements. Common plastic feedstocks include polyethylene, polypropylene, polystyrene, and PET, each with distinct melting points and decomposition characteristics. Unlike tire waste, plastic materials are typically homogeneous and require less complex pre-processing, allowing for simplified feeding systems in pyrolysis equipment configurations.

The lower melting points of most plastics, ranging from 120°C to 270°C, create different thermal management requirements compared to tire processing. Plastic pyrolysis equipment must accommodate rapid phase changes as materials transition from solid to liquid to vapor states. This characteristic demands precise temperature control systems and specialized reactor designs to prevent material degradation or incomplete conversion.

Plastic waste density variations significantly impact feeding system design in pyrolysis equipment. Low-density polyethylene films require different handling mechanisms compared to high-density rigid plastics. The equipment must accommodate varying bulk densities while maintaining consistent feeding rates to ensure stable pyrolysis reactions and optimal product yields.

Reactor Design and Configuration Differences

Tire Pyrolysis Reactor Specifications

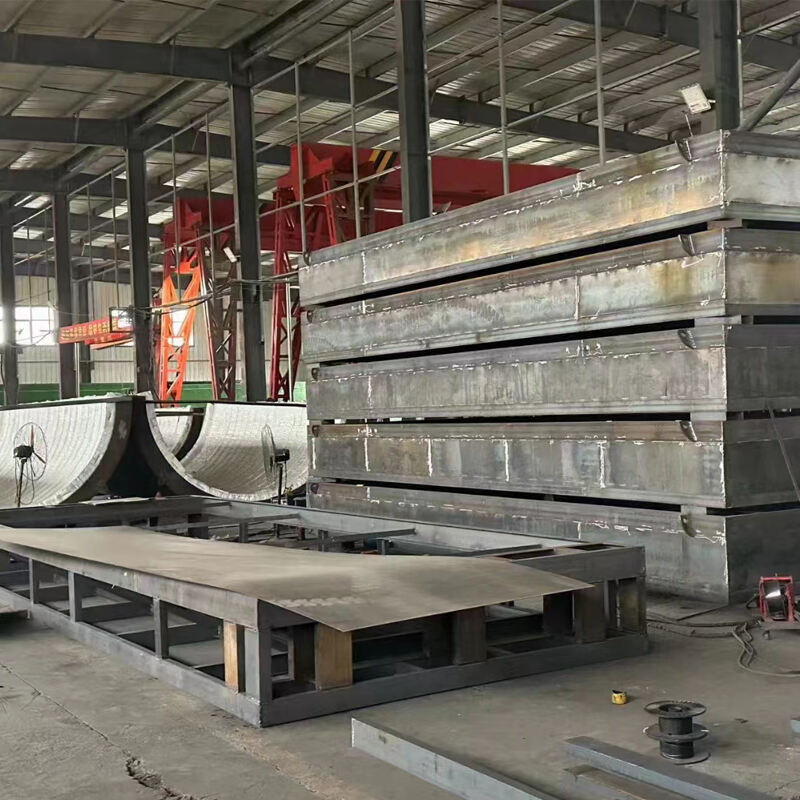

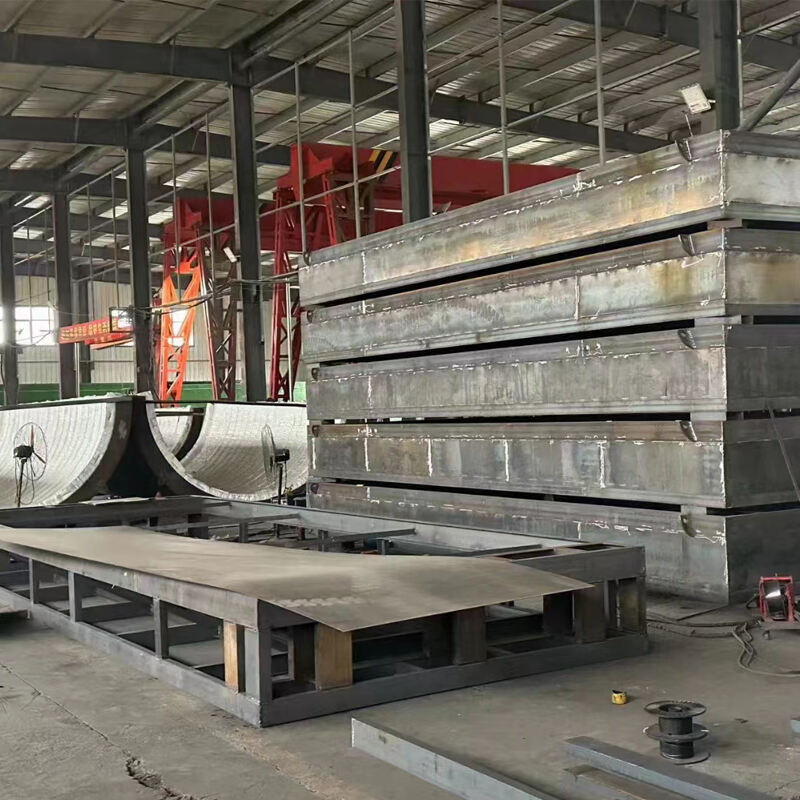

Tire-specific pyrolysis equipment typically employs rotary kiln reactors or horizontal batch reactors designed to handle the mechanical challenges of mixed materials. The reactor chamber must accommodate steel wire separation during the thermal decomposition process. Specialized internal mechanisms, such as rotating drums or agitation systems, ensure proper mixing and heat transfer while preventing steel wire accumulation that could impede operations.

The reactor shell thickness for tire pyrolysis equipment generally exceeds that required for plastic processing due to higher operating temperatures and mechanical stresses. Refractory lining specifications must withstand prolonged exposure to temperatures up to 500°C while maintaining structural integrity. Heat-resistant steel grades and specialized insulation systems are essential components of tire pyrolysis equipment to ensure long-term reliability.

Gas residence time requirements for tire pyrolysis typically range from 2-4 seconds, necessitating specific reactor volume calculations and gas flow management systems. The equipment design must facilitate proper vapor-solid separation while maintaining optimal thermal conditions throughout the decomposition process. Secondary cracking chambers are often integrated into tire pyrolysis equipment to enhance product quality and maximize hydrocarbon recovery rates.

Plastic Pyrolysis Reactor Configurations

Plastic pyrolysis equipment often utilizes different reactor configurations optimized for polymer decomposition characteristics. Fluidized bed reactors, screw conveyor systems, and continuous feeding mechanisms are commonly employed for plastic processing. These designs accommodate the lower viscosity of molten plastics and facilitate continuous operation modes that maximize processing throughput.

The reactor operating pressures for plastic pyrolysis equipment typically range from atmospheric to slightly positive pressures, contrasting with the higher pressure requirements of tire processing. This difference allows for lighter construction materials and simplified pressure management systems. However, plastic pyrolysis equipment must incorporate enhanced vapor recovery systems to capture the diverse hydrocarbon products generated during polymer breakdown.

Temperature gradient management becomes critical in plastic pyrolysis equipment due to the rapid thermal transitions of polymer materials. Multi-zone heating systems with independent temperature controls enable operators to optimize processing conditions for different plastic types. The equipment design must prevent hot spots that could cause premature degradation while ensuring complete thermal conversion throughout the reactor volume.

Product Recovery and Purification Systems

Tire-Derived Product Characteristics

Tire pyrolysis generates distinct product streams that require specialized recovery systems within the pyrolysis equipment configuration. The primary liquid product, tire-derived oil, contains complex hydrocarbon mixtures with higher molecular weights compared to plastic-derived oils. This characteristic necessitates enhanced condensation systems capable of efficiently recovering heavy oil fractions while maintaining product quality standards.

Carbon black recovery represents a significant value stream in tire pyrolysis operations, requiring specialized separation and collection systems integrated into the overall pyrolysis equipment design. The carbon black produced retains many properties suitable for various industrial applications, but requires proper handling and storage systems to prevent contamination. Equipment modifications include dedicated carbon black cooling and pneumatic transfer systems.

Steel wire recovery systems constitute essential components of tire pyrolysis equipment, designed to separate and collect metallic materials during or after the thermal decomposition process. Magnetic separation systems, screening mechanisms, and material handling equipment ensure efficient steel recovery while preventing interference with primary pyrolysis operations. The recovered steel wire typically maintains commercial value for steel industry applications.

Plastic-Derived Product Recovery

Plastic pyrolysis equipment generates lighter hydrocarbon products that require different recovery and purification approaches. The liquid products from plastic pyrolysis typically have lower boiling points and higher volatility, demanding specialized condensation systems with multiple cooling stages. Fractional distillation capabilities are often integrated into plastic pyrolysis equipment to enable product separation and quality enhancement.

Gas product recovery from plastic pyrolysis operations yields higher concentrations of valuable light hydrocarbons, including methane, ethane, and propane. The pyrolysis equipment must incorporate gas separation and purification systems capable of concentrating these valuable components for fuel applications or chemical feedstock purposes. Gas cleaning systems remove impurities and ensure product specifications meet end-use requirements.

Wax and heavy oil fractions from plastic pyrolysis require different handling approaches compared to tire-derived products. The lower viscosity and different chemical composition of plastic-derived products enable simplified pumping and storage systems. However, the equipment must accommodate potential solidification at ambient temperatures, requiring heated storage and transfer systems to maintain product fluidity.

Operational Control and Safety Considerations

Tire Processing Safety Requirements

Safety considerations for tire pyrolysis equipment encompass multiple hazards associated with mixed material processing. The presence of steel wire creates potential mechanical hazards that require specialized safety systems and operator protection measures. Equipment design must prevent steel wire entanglement in moving components while providing safe access for maintenance and inspection activities.

Thermal management safety systems for tire pyrolysis equipment must address higher temperature operations and potential hot spots caused by steel wire concentrations. Emergency cooling systems, temperature monitoring networks, and automatic shutdown procedures are essential safety features. The equipment must also accommodate thermal expansion stresses associated with mixed material processing and varying heat absorption rates.

Fire suppression systems for tire pyrolysis equipment require specialized design considerations due to the combustible nature of rubber materials and the presence of flammable vapors. Inert gas flooding systems, foam suppression capabilities, and emergency venting provisions ensure operator safety and equipment protection. Detection systems must monitor for both thermal anomalies and combustible gas concentrations throughout the processing facility.

Plastic Processing Safety Protocols

Plastic pyrolysis equipment safety systems focus primarily on vapor management and thermal control due to the rapid volatilization characteristics of polymer materials. Vapor detection systems monitor for hydrocarbon concentrations and provide early warning of potential safety hazards. The equipment design incorporates enhanced ventilation systems to prevent vapor accumulation in enclosed spaces.

Static electricity management becomes critical in plastic pyrolysis equipment due to the insulating properties of many polymer materials and the generation of fine particulates during processing. Grounding systems, anti-static additives, and humidity control measures prevent static charge accumulation that could create ignition sources. Equipment bonding and electrical continuity testing ensure comprehensive static protection.

Emergency response systems for plastic pyrolysis equipment must address rapid fire spread potential and toxic vapor generation. Automatic material feeding cutoff systems, emergency cooling procedures, and vapor containment measures provide multiple layers of protection. The equipment design facilitates rapid evacuation procedures while maintaining containment of hazardous materials during emergency situations.

Economic and Performance Considerations

Capital Investment Differences

Initial capital requirements for tire pyrolysis equipment typically exceed those for plastic processing systems due to the robust construction necessary for mixed material handling. The specialized steel separation systems, enhanced thermal management, and strengthened reactor components increase equipment costs. However, the multiple valuable product streams from tire pyrolysis can provide attractive return on investment scenarios for operators.

Plastic pyrolysis equipment generally requires lower initial investment due to simplified material handling requirements and standard reactor configurations. The homogeneous nature of plastic feedstocks allows for more standardized equipment designs and manufacturing approaches. This cost advantage must be balanced against potentially lower product diversity and market value compared to tire processing operations.

Maintenance cost considerations differ significantly between tire and plastic pyrolysis equipment due to operating condition variations. Tire processing systems typically require more frequent maintenance due to abrasive materials and steel wire handling. Plastic processing equipment may have lower maintenance requirements but requires specialized attention to vapor handling systems and product recovery components.

Operational Efficiency Metrics

Tire pyrolysis equipment efficiency measurements encompass multiple product streams and recovery rates. Typical tire processing yields include 35-45% liquid oil, 30-35% carbon black, 10-15% steel wire, and 10-15% gas products. Equipment design optimization focuses on maximizing overall material recovery while maintaining product quality standards. Processing throughput rates generally range from 5-20 tons per day depending on reactor size and configuration.

Plastic pyrolysis equipment performance metrics emphasize liquid hydrocarbon yield optimization and energy efficiency. Plastic processing typically achieves 70-85% liquid product yields with 10-15% gas production and minimal solid residue. The higher liquid yields and simplified product recovery systems can result in superior economic performance despite potentially lower individual product values compared to tire processing operations.

Energy consumption patterns differ between tire and plastic pyrolysis equipment due to temperature requirements and processing characteristics. Tire systems typically require higher energy inputs for reaching optimal processing temperatures but benefit from internal heat generation during rubber decomposition. Plastic processing systems operate at lower temperatures but may require additional energy for complete polymer conversion and vapor recovery operations.

Future Technology Developments

Advanced Tire Processing Technologies

Emerging developments in tire pyrolysis equipment focus on automated steel separation systems and enhanced carbon black purification capabilities. Advanced magnetic separation technologies and automated sorting systems reduce manual labor requirements while improving product quality. Research into catalytic pyrolysis processes aims to upgrade tire-derived oils to higher-value products through integrated equipment modifications.

Continuous processing systems for tire pyrolysis equipment represent significant technological advancement opportunities. Current batch processing limitations restrict throughput rates and increase operational complexity. Development of continuous tire feeding and steel separation systems could revolutionize tire pyrolysis equipment efficiency and economic viability for large-scale operations.

Environmental performance improvements in tire pyrolysis equipment address emission reduction and energy recovery optimization. Advanced gas cleaning systems and waste heat recovery technologies enhance overall sustainability while reducing operational costs. Integration of renewable energy sources and process optimization through artificial intelligence systems represent future development directions for tire processing technologies.

Plastic Processing Innovation Trends

Plastic pyrolysis equipment innovations focus on feedstock flexibility and product selectivity improvements. Advanced reactor designs accommodate mixed plastic waste streams while maintaining product quality through selective thermal cracking processes. Development of modular equipment configurations enables operators to process diverse plastic types within single systems while optimizing product distributions.

Catalytic upgrading systems integrated into plastic pyrolysis equipment enhance product value through selective conversion processes. These advanced systems convert low-value pyrolysis products into higher-grade fuels and chemical feedstocks. Equipment modifications incorporate catalyst regeneration systems and product separation technologies to maximize economic returns from plastic waste processing operations.

Digital monitoring and control systems represent major advancement areas for plastic pyrolysis equipment. Real-time composition analysis, predictive maintenance capabilities, and automated process optimization improve operational efficiency while reducing manual oversight requirements. Integration of blockchain technology and supply chain tracking systems enhance product quality assurance and market acceptance of recycled materials.

FAQ

What are the main structural differences between tire and plastic pyrolysis reactors

Tire pyrolysis reactors require significantly more robust construction due to the presence of steel wire and higher operating temperatures. They typically feature thicker reactor walls, specialized steel separation mechanisms, and enhanced thermal management systems. Plastic pyrolysis reactors can utilize lighter construction materials and simpler internal configurations due to the homogeneous nature of plastic feedstocks and lower processing temperatures. The reactor geometry also differs, with tire systems often employing rotary designs while plastic systems may use fluidized beds or continuous screw conveyors.

How do product yields compare between tire and plastic pyrolysis operations

Tire pyrolysis typically yields 35-45% liquid oil, 30-35% carbon black, 10-15% steel wire, and 10-15% gas products, providing multiple revenue streams but lower liquid yields. Plastic pyrolysis generally produces 70-85% liquid hydrocarbons with 10-15% gas and minimal solid residue, resulting in higher liquid product yields but fewer diversified products. The economic value comparison depends on market conditions for each product type, with tire processing offering more stable returns through diversified products while plastic processing maximizes liquid fuel production.

What safety considerations are unique to each type of pyrolysis equipment

Tire pyrolysis equipment requires specialized safety measures for steel wire handling, including entanglement prevention systems and mechanical hazard protection. The higher operating temperatures and mixed materials create additional thermal management and fire suppression requirements. Plastic pyrolysis equipment safety focuses primarily on vapor management due to rapid volatilization, requiring enhanced ventilation systems and static electricity control measures. Both systems require comprehensive emergency response procedures, but tire equipment emphasizes mechanical safety while plastic equipment prioritizes vapor containment and ignition prevention.

Can the same equipment be modified to process both tire and plastic waste

While some equipment components can be shared between tire and plastic processing, significant modifications are typically required for effective dual-purpose operation. The fundamental differences in material properties, temperature requirements, and product recovery systems make dedicated equipment more practical for commercial operations. However, modular equipment designs are being developed that allow operators to reconfigure systems for different feedstocks through component exchanges. The economic viability of dual-purpose systems depends on processing volumes, product markets, and operational flexibility requirements for specific applications.

Hot News

Hot News