Razumijevanje industrijskih destilacijskih sustava i njihove kritične uloge

Oprema za destilaciju čini temelj mnogih industrijskih procesa, od rafiniranja petrokemijskih proizvoda do proizvodnje lijekova. Ova sofisticirana tehnologija omogućuje odvajanje tekućih mješavina na temelju razlika u isparljivosti, čime postaje nezaobilazna za proizvodnju visokokvalitetnih proizvoda. Odabir odgovarajuće destilacijske opreme može znatno utjecati na operativnu učinkovitost, kvalitetu proizvoda i ukupan poslovni uspjeh.

Moderne industrijske tvornice u velikoj mjeri se oslanjaju na točne procese separacije, a odabir prave destilacione opreme zahtijeva pažljivo razmatranje više čimbenika. Bez obzira na to širite li postojeće operacije ili postavljate novu tvornicu, razumijevanje detalja destilacijskih sustava pomoći će osigurati optimalnu učinkovitost i povrat ulaganja.

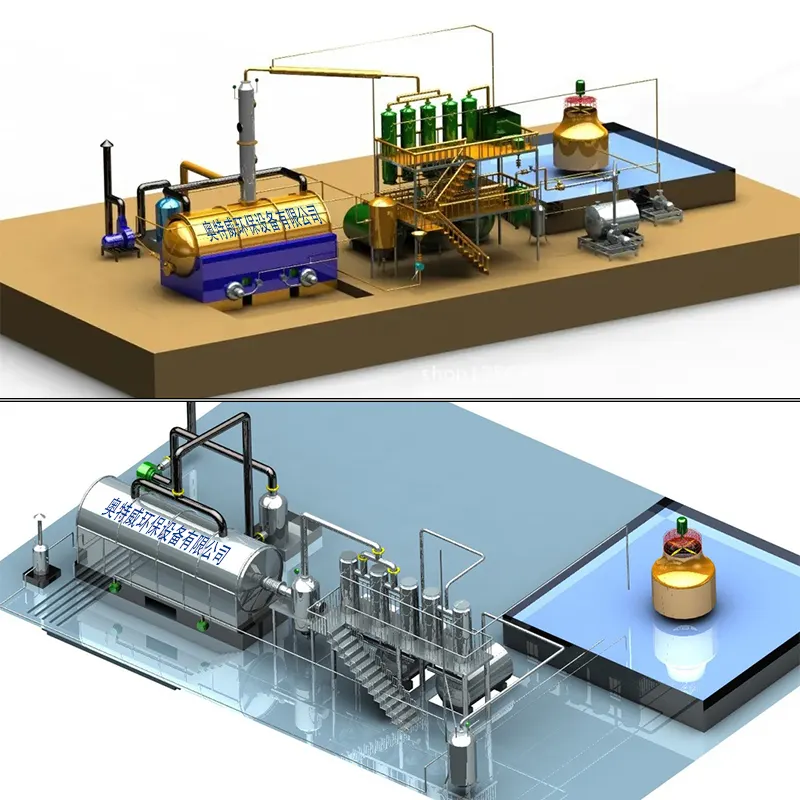

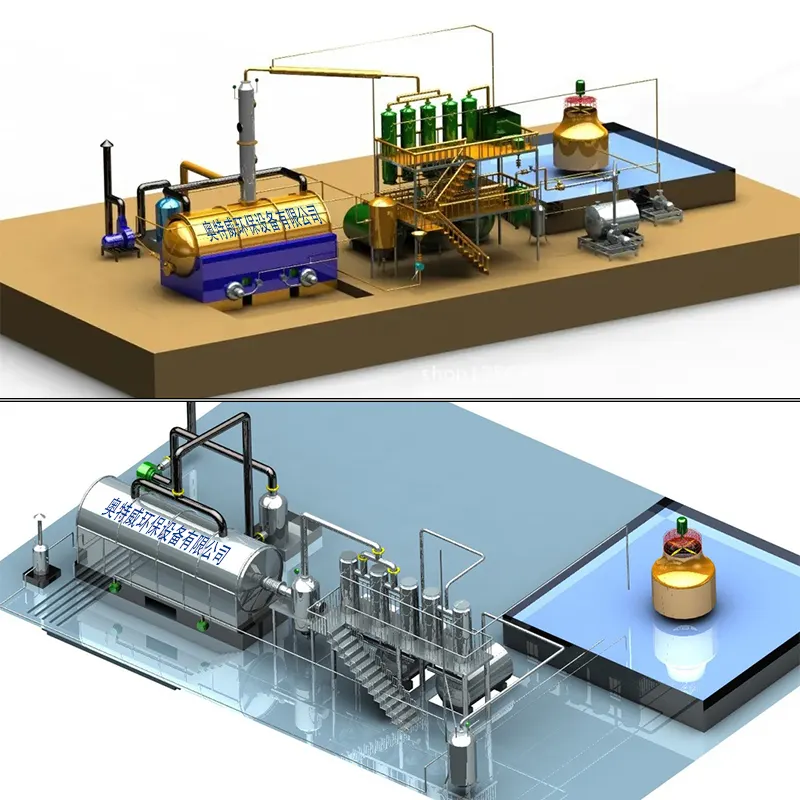

Ključne komponente industrijskih destilacijskih sustava

Bitne hardverske komponente

Tema svakog destilacijskog sustava leži u njegovim osnovnim komponentama. Destilacijska kolona služi kao primarni spremnik u kojem se odvija separacija, a obično ima više stupnjeva ili ploča za učinkovitu separaciju komponenata. Unutarnji dijelovi kolone, uključujući ploče, nasipna tijela i distributore, igraju ključnu ulogu u maksimiziranju kontakta između parnog i tekućeg faznog stanja.

Reboileri i kondenzatori rade u tandemu kako bi održali odgovarajuće termalne gradijente kroz cijeli sustav. Reboiler osigurava unos topline za isparavanje, dok kondenzator omogućuje hlađenje i prikupljanje destiliranih produkata. Pomoćne komponente poput pumpe, ventila i sustava za upravljanje osiguravaju glatko funkcioniranje i preciznu kontrolu procesa.

Automatizacija i kontrolni sustavi

Suvremena oprema za destilaciju uključuje sofisticirane značajke automatizacije koje poboljšavaju operativnu učinkovitost. Senzori temperature, manometri i mjerači protoka pružaju podatke u stvarnom vremenu za optimizaciju procesa. Napredni sustavi upravljanja omogućuju automatske prilagodbe za održavanje optimalnih radnih uvjeta, smanjujući potrebu za stalnim ručnim intervencijama.

Mogućnosti integracije s kontrolnim sustavima cijele tvornice omogućuju bezproblémno funkcioniranje i prikupljanje podataka. Ova povezanost omogućuje planiranje preventivnog održavanja i optimizaciju performansi na temelju povijesnih operativnih podataka.

Tehničke specifikacije i razmatranja o performansama

Kapacitet i zahtjevi za propusnošću

Kada odabirete destilacionu opremu, točna procjena zahtjeva za kapacitetom je ključna. Uzmite u obzir trenutne potrebe proizvodnje i moguću buduću proširenja. Sustav bi trebao izdržati različite brzine dovoda i istovremeno održavati učinkovitost odvajanja. Veća oprema pruža operativnu fleksibilnost, ali može dovesti do nepotrebnih kapitalnih izdataka.

Rasponi radnog tlaka i zahtjevi za temperaturom moraju biti usklađeni s procesnim specifikacijama. Operacije pod visokim tlakom mogu zahtijevati posebne materijale i sigurnosne značajke, dok sustavi za destilaciju pod vakuumom zahtijevaju dodatne razmisliti o brtvljenju i kontroli tlaka.

Kompatibilnost materijala i izvedba

Odabir građevinskog materijala znatno utječe na trajnost opreme i čistoću proizvoda. Nehrđajući čelik ostaje popularan zbog otpornosti na koroziju i izdržljivosti, ali specijalizirane aplikacije mogu zahtijevati egzotične legure ili opremu obloženu staklom. Razmotrite kemijsku kompatibilnost svih dijelova izloženih tekućinama i sredstvima za čišćenje.

Zahtjevi glede površinske obrade, posebno u farmaceutskim i aplikacijama namijenjenim za hranu, mogu utjecati na odabir materijala i metode izrade. Pravilno dokumentiranje certifikata o materijalima i izvješća o ispitivanjima osigurava sukladnost s industrijskim standardima i regulatornim zahtjevima.

Ekonomski i operativni aspekti

Investicijski i operativni troškovi

Početni kapitalni trošak predstavlja samo dio ukupnih troškova vlasništva za destilacijsku opremu. Potrošnja energije često čini značajan dio operativnih troškova. Dizajni visoke učinkovitosti i opcije integracije topline mogu znatno smanjiti troškove komunalija tijekom vijeka trajanja opreme.

Zahtjevi za održavanje i dostupnost rezervnih dijelova utječu na dugoročne operativne troškove. Odabir opreme od utvrđenih proizvođača osigurava pouzdanu podršku i dostupnost dijelova. Razmotrite omjer troškova i korisnosti automatiziranih značajki koje mogu smanjiti potrebe za radnom snagom i poboljšati operativnu učinkovitost.

Zahtjevi za prostor i razmatranja pri instalaciji

Fizička ograničenja prostora često utječu na odabir i konfiguraciju opreme. Za vertikalne zahtjeve za visokim stupovima potrebno je uzeti u obzir pristup za instalaciju i održavanje. Razmotrite lokaciju pomoćne opreme i priključaka za komunalne usluge pri planiranju konfiguracija rasporeda.

Zahtjevi za instalaciju mogu uključivati posebne temelje, strukturne potpore i radne platforme. Pravilno planiranje isporuke i sastavljanja opreme može spriječiti skupocene kašnjenja i izmjene tijekom instalacije.

Sigurnost i pridržavanje propisima

Sigurnosne značajke i zahtjevi

Oprema za industrijsku destilaciju mora uključivati odgovarajuće sigurnosne značajke kako bi se zaštitili osoblje i objekti. Sustavi za otpuštanje tlaka, mogućnosti hitnog zaustavljanja i odgovarajuća ventilacija su važne razmatranja. Zahtjevi za zaštitu od požara mogu utjecati na razmještanje opreme i odabir materijala.

Klasifikacije opasnih zona utječu na odabir električnih i instrumentacijskih komponenata. Pravilno dokumentiranje sigurnosnih značajki i postupaka rada olakšava pridržavanje propisa i obuku operatera.

Ekološki i regulatorni standardi

Ekološki propisi često određuju zahtjeve za kontrolu emisija i postupke rukovanja otpadom. Uzmite u obzir potrebu za sustavima za povraćaj para i značajkama za sadržavanje. Zahtjevi za dokumentaciju za ekološke dozvole mogu utjecati na odabir opreme i mogućnosti praćenja.

Industrijski specifične regulative mogu nametnuti dodatne zahtjeve u odabiru materijala i konstrukcijskim značajkama. Održavanje odgovarajuće dokumentacije mjera usklađenosti osigurava glatke inspekcije i rad pod nadzorom.

Često postavljana pitanja

Koji čimbenici najznačajnije utječu na učinkovitost destilacijske opreme?

Primarni čimbenici koji utječu na učinkovitost destilacijske opreme uključuju konstrukciju kolone i odabir unutarnjih elemenata, kontrolu radnog tlaka i temperature, dosljednost kvalitete sirovine te prakse pravilnog održavanja. Optimalna učinkovitost zahtijeva pažljivu ravnotežu ovih elemenata uz redovito praćenje i prilagodbu radnih parametara.

Kako se potrošnja energije može optimizirati u destilacijskim procesima?

Strategije optimizacije energije uključuju uvođenje sustava za integraciju topline, odabir učinkovitih unutarnjih dijelova stupova, održavanje odgovarajuće izolacije te korištenje naprednih sustava upravljanja. Redovito održavanje površina za izmjenu topline i optimizacija radnih uvjeta također doprinose smanjenju potrošnje energije.

Ključna pitanja održavanja za destilacijsku opremu?

Bitna pitanja održavanja uključuju redovni pregled unutarnjih dijelova stupova, praćenje brzine korozije, održavanje mehaničkih brtvila i zaptivki, kalibraciju instrumenata te čišćenje površina za izmjenu topline. Primjena programa prevencije pomaže u osiguranju pouzdanog rada i produženju vijeka trajanja opreme.

Vruće vijesti

Vruće vijesti